While rotogravure printing is widely known for its role in packaging and labels, its true artistry shines in the world of decorative paper. This is the paper that brings life to our living spaces, from the grain of a laminated floor to the texture of kitchen countertops and the intricate patterns of furniture. Here, rotogravure isn’t just about putting ink on paper; it's about replicating nature and design with stunning realism and durability.

The Heart of Realism: Why Rotogravure Excels

The power of rotogravure lies in its ability to create photorealistic images with unparalleled depth and subtlety. This is achieved through the same core principle as with labels: an engraved cylinder with millions of tiny, recessed cells. For decorative paper, these cylinders are meticulously crafted to reproduce the fine details of wood grain, the veining of marble, or the subtle textures of fabric. The varying depths of the cells allow for a smooth transition between light and dark tones, capturing the three-dimensional feel of a natural surface.

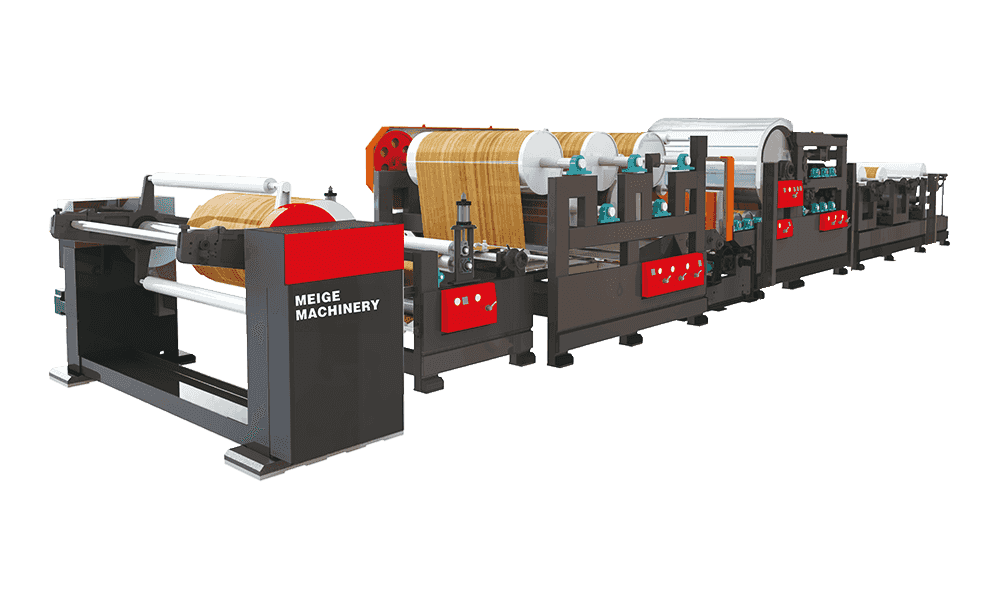

A Rotogravure Machine designed for decorative paper is a marvel of precision engineering. Unlike label machines that print on narrow rolls, these machines handle wide, continuous rolls of paper, often several meters wide. This is essential for ensuring that the final product, whether a kitchen countertop or a piece of furniture, has a seamless, continuous pattern without jarring repeats. The sheer size and speed of a Rotogravure Machine make it the only viable option for the high-volume production required by the global furniture and flooring industries.

The Unsung Product: From Plain Paper to Decorative Masterpiece

The process begins with a plain paper substrate, often a specialized paper that is designed for saturation with resins later in the production process. This paper web is fed into the Rotogravure Machine, where it passes through a series of printing stations. Each station corresponds to a specific color, but these aren't just your standard CMYK inks. Decorative paper designs often utilize specialized inks to mimic the natural colors of wood, stone, and other materials. A design replicating oak, for example, might use a series of browns, tans, and blacks to build up the complex visual texture of the wood grain.

After the design is printed, the paper is dried and cured. The printed decorative paper is then treated with a clear resin, which is what gives the final product its durability and scratch resistance. This is where the magic of the rotogravure print truly comes to life. The high-resolution image, once saturated with resin and pressed onto a substrate like particleboard or MDF, becomes a durable, long-lasting surface that can withstand daily use. The intricate details printed by the Rotogravure Machine are now locked in, protected from wear and tear.

Applications: The Ubiquitous Presence of Decorative Paper

The use of rotogravure-printed decorative paper is widespread, appearing in products we interact with every day:

-

Laminate Flooring: The high-resolution, wood-grain patterns that make laminate flooring so popular are a direct result of rotogravure printing.

-

Furniture and Cabinetry: The "wood veneer" on many modern bookshelves, desks, and kitchen cabinets is, in fact, decorative paper meticulously printed to look like natural wood.

-

Countertops: High-pressure laminates used for kitchen and bathroom countertops often feature patterns that mimic the look of expensive granite, marble, or stone.

-

Doors and Paneling: Rotogravure is used to create realistic textures for interior doors and wall panels, offering a cost-effective alternative to solid wood.