Industry knowledge

How does the gravure coating process work specifically in the context of decorative paper?

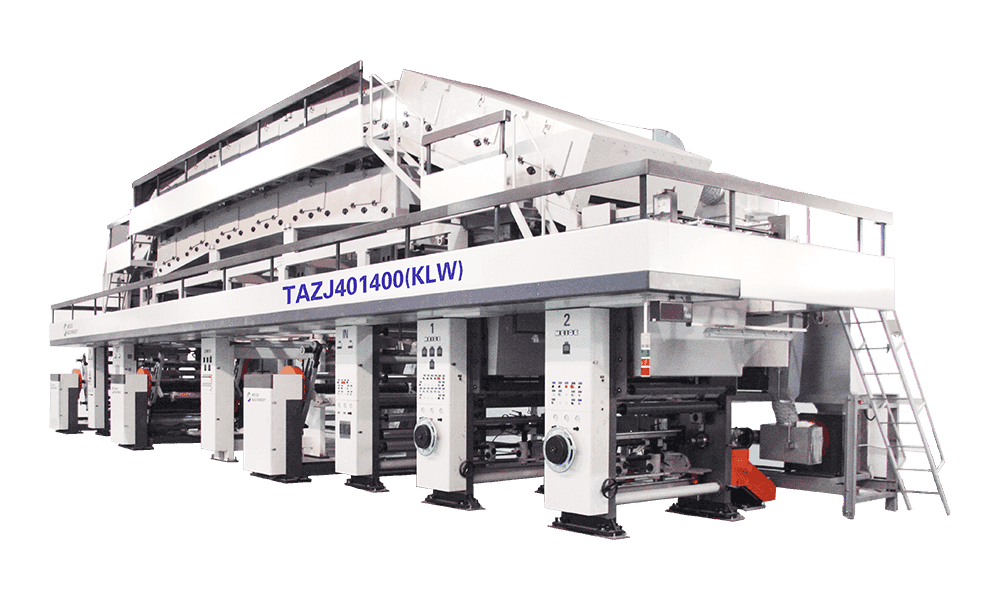

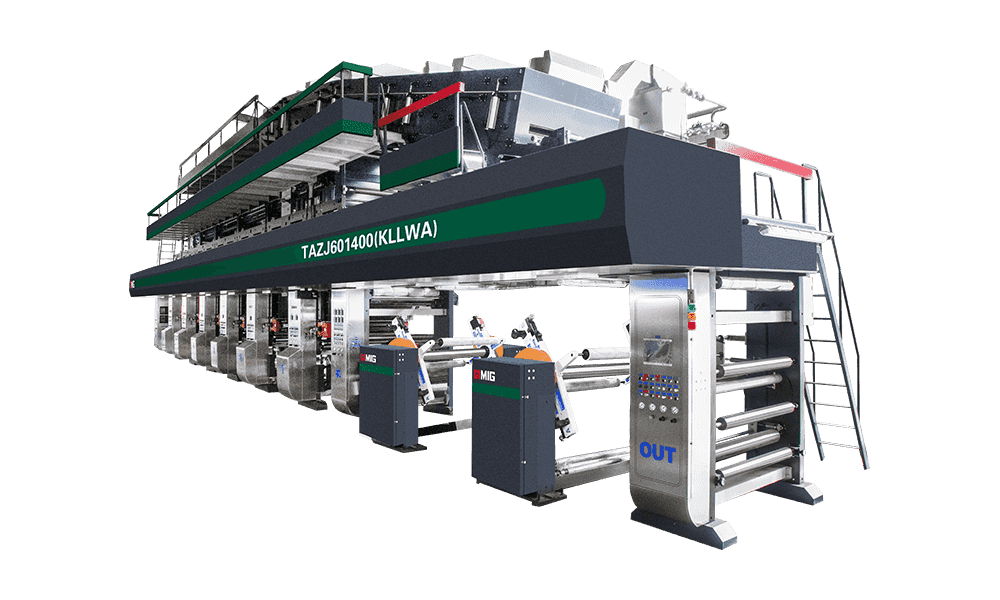

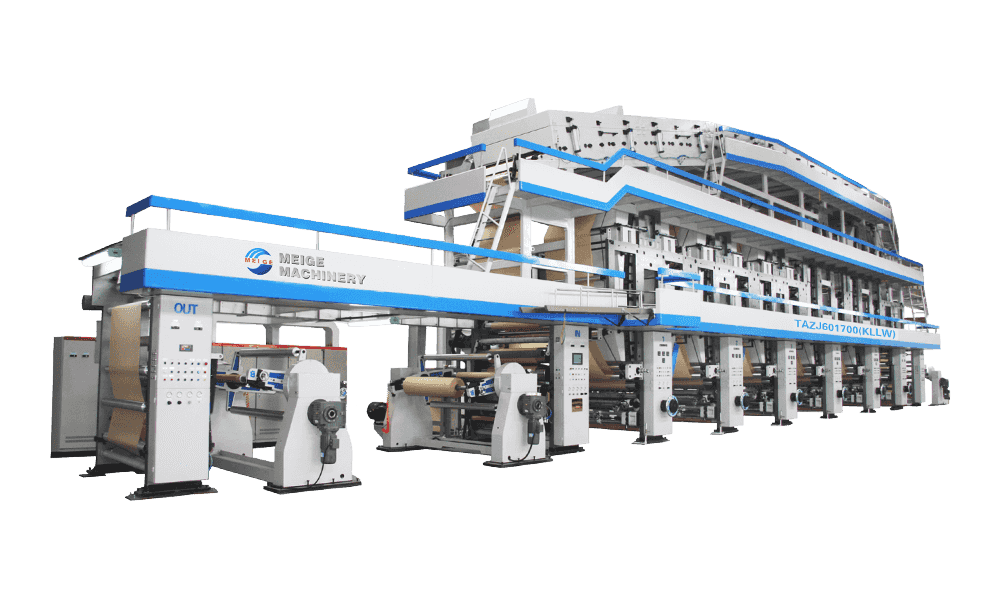

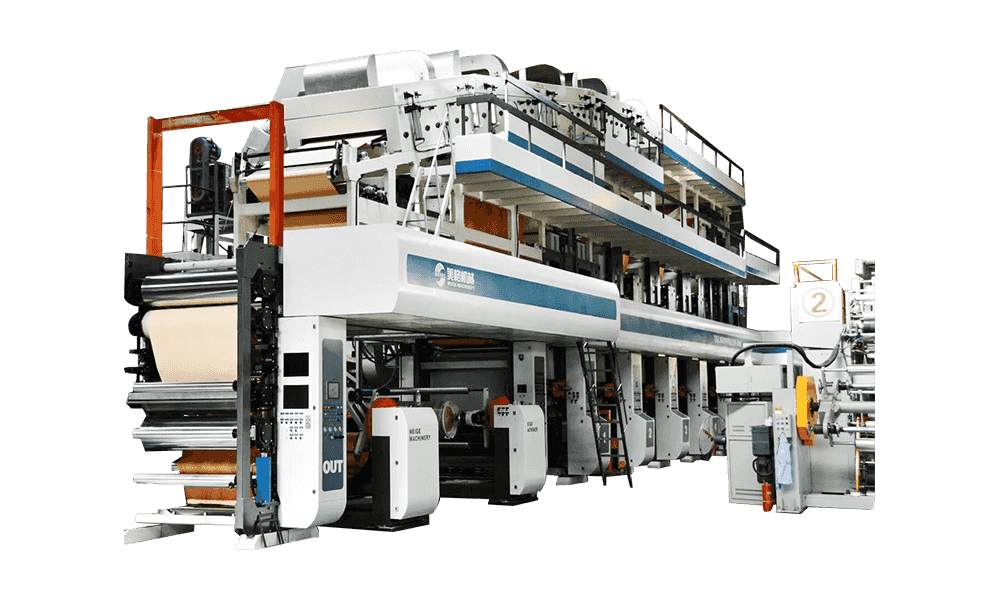

It's the secret behind those incredibly detailed and vibrant designs you see on everything from furniture laminates to flooring. Unlike some other printing methods, gravure excels at achieving fine details, rich colors, and consistent quality, making it the go-to for high-end decorative applications. Companies like Zhejiang Meige Machinery Co., Ltd., a national high-tech enterprise founded in 1999, are at the forefront of developing the intelligent and automated gravure printing machines that make this possible, including their LLW Decorative Paper Gravure Coating Machine series, specializing in equipment for decorative paper and films.

Here's a step-by-step look at how it brings decorative paper to life:

1. The Engraved Heart: The Gravure Cylinder

Everything starts with the gravure cylinder. Imagine a finely crafted metal cylinder, often made of steel with a copper and chrome finish for durability. The magic happens here: the desired decorative pattern – whether it's a realistic woodgrain, a subtle fabric texture, or a bold abstract design – is precisely engraved onto its surface.

These engravings aren't just lines; they're tiny, recessed "cells" that vary in depth and size. This variation is key:

Deeper, larger cells hold more ink or coating, creating darker, richer, and more intense areas in the final design.

Shallower, smaller cells hold less, resulting in lighter tones, finer details, and smooth gradations.

This intricate cell structure is what gives gravure its unmatched ability to render subtle shading and lifelike imagery. Engraving can be done mechanically, electronically (often with lasers for ultimate precision), or chemically.

2. Ink/Coating Immersion & Precision Scraping

As the gravure cylinder rotates, it dips into a pan filled with the liquid – whether it's ink, varnish, an adhesive, or a special protective coating. The engraved cells greedily fill up with this liquid.

Next, as the cylinder continues its journey, it meets the doctor blade. This isn't just any blade; it's a precisely angled and pressured scraper that swiftly and cleanly removes all excess ink or coating from the non-engraved, smooth surface of the cylinder. Only the ink nestled within the microscopic cells remains, poised for transfer. This step is crucial for preventing smudges and ensuring crisp, clean prints.

3. The Transfer: From Cylinder to Paper

Now, the decorative paper, often called the "substrate" or "web," enters the scene. It's fed from a large roll and guided between the ink-filled gravure cylinder and a supportive impression roller (typically rubber-coated).

At this "nip point," the impression roller applies consistent pressure, effectively pressing the decorative paper against the gravure cylinder. This pressure, combined with the natural pull of capillary action, draws the ink or coating directly and completely out of the engraved cells and onto the paper's surface. Zhejiang Meige Machinery Co., Ltd. excels in this area, offering various series of LLW Gravure Coating Machine for Engineered Wood Decorative Paper (also referred to as drum decorative paper intaglio printing machine series) that are widely utilized in the engineered wood decorative materials and ubiquitous household industries. In fact, Meige Machinery holds an impressive market share of approximately 60% in domestic engineered wood decorative paper printing presses, demonstrating their expertise in this core process.

4. Drying & Curing: Setting the Design

Immediately after the transfer, the newly coated decorative paper races into a drying or curing unit. This unit blasts it with heat (from sources like thermal oil, gas, or electricity) or exposes it to UV/EB light. The goal is rapid evaporation of solvents (for traditional inks/coatings) or quick curing (for UV/EB formulations). Fast drying is critical to prevent smearing and to prepare the paper for subsequent processes, like adding another color layer or a protective topcoat.

5. Multi-Layer Magic: Building Complex Designs

For multi-color designs or products requiring several protective layers (e.g., a base color, a woodgrain pattern, and then a clear protective topcoat), the decorative paper will pass through a series of gravure printing units. Each unit applies a different color or coating in perfect sequence.

Modern machines, like those developed by Meige Machinery, located in Lin'an District, Hangzhou City, Zhejiang Province, use sophisticated automatic registration control systems to ensure that each successive layer aligns flawlessly with the previous one, maintaining the integrity and beauty of the overall design. Their product range also includes PVC, PP decorative film intaglio printing machine series and PVC film multi-layer non-adhesive composite embossing production lines, where they hold about a 50% market share domestically.

6. The Final Roll: Ready for Its Purpose

Once all the coatings are applied and thoroughly dried, the decorative paper is either neatly rewound onto a finished roll or precisely cut into sheets. It's now ready for its next transformation, perhaps to be impregnated with resins, laminated onto furniture boards, or used in other decorative applications. Meige Machinery's dedication to research and development, backed by over 20 years of technology accumulation, has led to products widely used in the engineered wood decorative materials, ubiquitous household, and textile transfer printing industries. Their equipment, including their textile transfer printing paper (film) intaglio printing machine series, is domestically leading and exported to international markets across Europe, America, the Middle East, and Southeast Asia.

Why Gravure Excels for Decorative Paper (and why companies like Meige Machinery are vital):

Unmatched Detail & Quality: The engraved cells allow for incredible fidelity, sharp lines, and smooth tonal gradations – essential for realistic woodgrains and intricate patterns.

Consistent Results: Gravure delivers exceptional uniformity over long production runs, ensuring every meter of decorative paper looks consistent.

Durability & Speed: The robust cylinders handle high volumes, making gravure very cost-effective for mass production, and the machines operate at impressive speeds.

Coating Versatility: It can apply a wide range of coatings, from vibrant inks and lacquers to protective layers and specialized functional coatings.

Through the continuous innovation of companies like Zhejiang Meige Machinery Co., Ltd., the gravure coating process remains a cornerstone in the production of high-quality decorative papers and films globally.

English

English 中文简体

中文简体