What is Lamination and Why Does it Matter?

Lamination is an ingenious manufacturing process that involves bonding two or more layers of material together to create a composite product with superior qualities. By combining different materials, manufacturers can achieve enhanced strength, stability, acoustic insulation, aesthetic appeal, or a combination of these properties. Think of it as a technological sandwich, where each layer contributes a specific benefit. This simple, yet powerful, technique is essential across numerous industries, from creating durable wood flooring and shatter-resistant glass to the protective film on your smartphone screen.

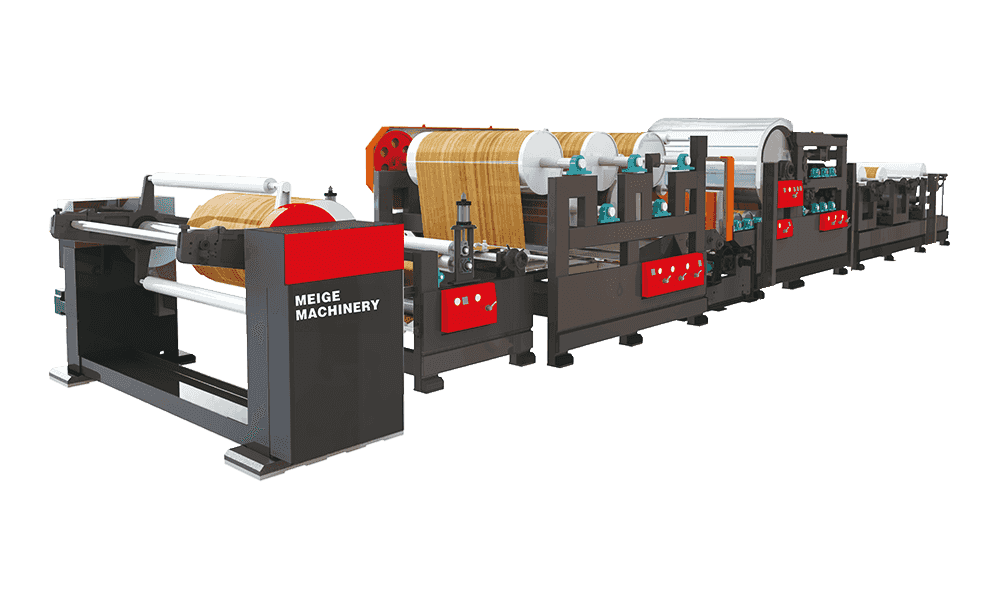

The Core Technology: How a PVC Laminating Machine Works

A PVC Laminating Machine is a specialized piece of industrial equipment engineered to bond a layer of Polyvinyl Chloride (PVC) film—often decorative or protective—onto a substrate material, which can be anything from wood-based panels (like MDF or chipboard) to PVC profiles used for window frames.

The Lamination Process

The process generally follows a few critical steps:

- Preparation: The substrate material (e.g., a window profile or a furniture panel) is thoroughly cleaned and prepared. For many PVC applications, a primer is applied to ensure maximum adhesion between the substrate and the PVC film.

- Adhesive Application: A specialized adhesive, frequently a hot-melt glue like EVA (Ethylene-Vinyl Acetate) or PUR (Polyurethane Reactive), is applied, either to the substrate or directly to the PVC foil. The choice of adhesive is crucial, as it determines the final product’s resistance to heat, moisture, and wear.

- Bonding and Pressure: The PVC film, which is typically fed from a large roll, is brought into contact with the adhesive-coated substrate. The assembly then passes through a series of heated pressure rollers (or a flat press). These rollers apply precise, continuous pressure while the heat activates the adhesive, forming a strong, permanent bond.

- Finishing: The newly laminated product is cooled, often trimmed to size, and may undergo further quality checks before being stacked or sent for subsequent processing. Modern machines boast high levels of automation, using sensors and smart controls to maintain consistent temperature, pressure, and alignment, ensuring a wrinkle-free, bubble-free, and high-quality finish every time.

PVC Lamination: Applications that Touch Your Daily Life

The capability of the PVC Laminating Machine to efficiently and consistently bond PVC films has revolutionized several product categories. The versatility of PVC film—available in numerous colors, textures, and patterns (including realistic wood grains and metallic finishes)—is what makes the machinery so indispensable.

Windows and Doors

Perhaps the most widespread use is in the fenestration industry (windows and doors). PVC window frames, which are inherently durable and energy-efficient, can be laminated with decorative PVC foils to give them a customized look. This allows homeowners to have, for instance, a beautiful dark wood-grain finish without the maintenance of actual wood, while also boosting the profile’s resistance to UV rays and weathering.

Furniture and Interior Surfaces

In the world of furniture, PVC lamination is used extensively to create cabinet doors, shelves, and other flat panels. The laminated surface is easy to clean, highly resistant to scratches and moisture, and offers designers a virtually limitless palette of finishes. From modern high-gloss to textured matte, the aesthetic flexibility of laminated panels keeps up with the latest interior design trends.

Protective Films

Beyond decorative uses, PVC laminators are also used to apply transparent or low-tack protective films to sensitive surfaces like metal or plastic sheets during the manufacturing or transportation process, shielding them from damage until they reach the final consumer.

The Future of Lamination: Efficiency and Customization

As demand for customized products grows, the sophistication of the PVC Laminating Machine continues to advance. Manufacturers are focused on improving machine flexibility, allowing for quicker changeovers between different profile shapes and foil types. Integrating lamination directly into the extrusion line—a process known as inline lamination—is a key development, offering significant time and cost savings by eliminating the need to transport and reheat materials. The industrial laminator, particularly the PVC variant, is a quiet powerhouse, consistently delivering the quality, durability, and aesthetics that define countless modern products.