What a Decorative Paper Gravure Printer Is Used For

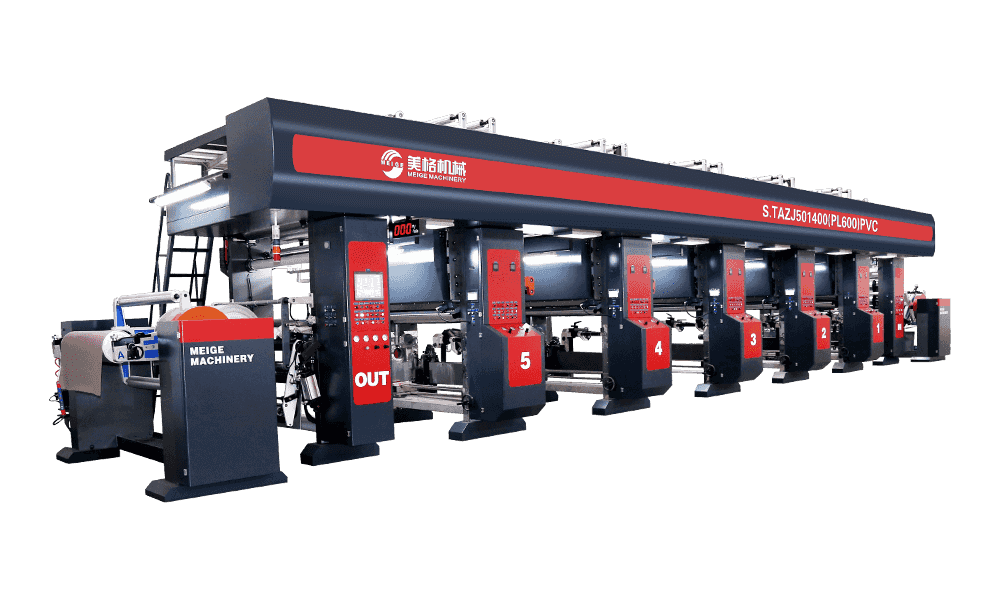

A Decorative Paper Gravure Printer is a specialized printing machine designed to apply patterns, colors, and textures onto decorative base paper with high precision. This type of printer is widely used in industries such as furniture, flooring, doors, wall panels, and laminate production. The printed paper later becomes part of finished surfaces that imitate wood grain, stone, marble, or abstract designs.

Unlike basic printing equipment, gravure printing focuses on consistency and depth of color. The engraved cylinders allow ink to settle into fine grooves, resulting in sharp details and stable color reproduction across long production runs.

Core Working Principle of Gravure Printing on Decorative Paper

The working process of a decorative paper gravure printing machine is straightforward but highly precise. Each engraved cylinder carries a specific color or pattern layer. Ink fills the engraved cells, excess ink is wiped away, and pressure transfers the ink onto the paper surface.

- Engraved cylinders determine pattern clarity and repeat accuracy

- Doctor blades control ink thickness and uniformity

- Drying units ensure fast ink curing between color layers

This system allows continuous printing at high speed without sacrificing design accuracy, which is critical for large-scale decorative paper production.

Key Features That Matter in Daily Production

When manufacturers select a decorative paper gravure printer, they focus on performance features that affect efficiency and product quality. These machines are built for long operating hours and stable output.

| Feature |

Production Benefit |

| Multi-color printing units |

Complex and layered design capability |

| High-speed web handling |

Improved output and lower unit cost |

| Automatic tension control |

Reduced paper waste and misalignment |

Why Gravure Printing Is Preferred for Decorative Paper

Compared with digital or flexographic methods, gravure printing offers better consistency for mass production. Once cylinders are prepared, the machine can run continuously with minimal variation in color tone or pattern repeat.

For decorative surfaces where visual realism is critical, gravure printing delivers deeper ink penetration and smoother gradients, making wood grain and stone textures look more natural.