The Mechanics of Rotogravure Excellence

The rotogravure machine stands as a pinnacle of industrial printing technology, specifically engineered for high-speed, long-run production. Unlike flexography, which uses raised plates, rotogravure utilizes an intaglio process where the image is chemically etched or laser-engraved into the surface of a metal cylinder. During operation, this cylinder is partially submerged in an ink fountain. As it rotates, ink fills the recessed microscopic cells. A precision "doctor blade" then scrapes the excess ink from the non-image surface, ensuring that only the ink within the cells is transferred to the substrate as it passes between the gravure cylinder and an impression roller.

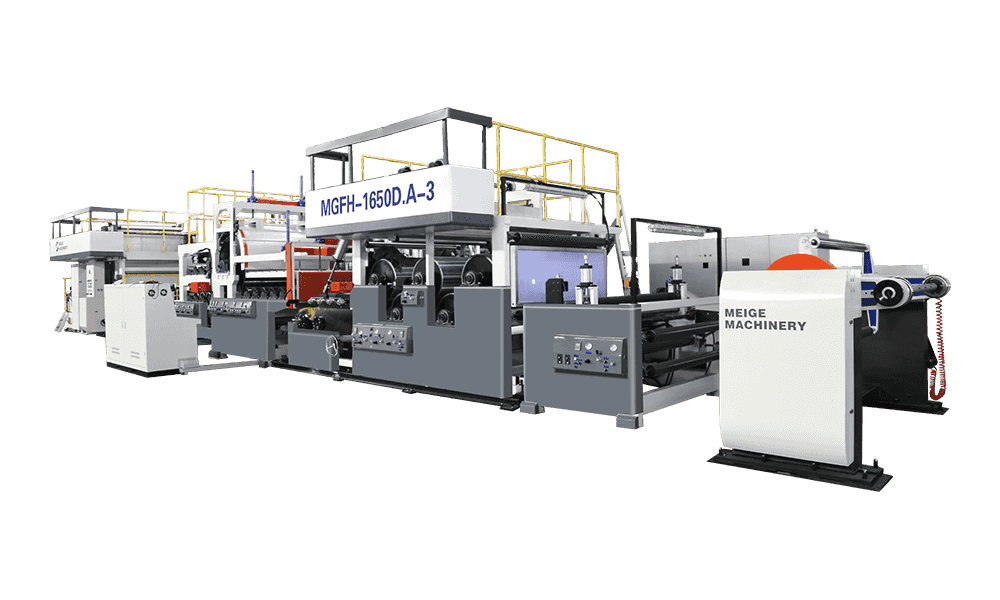

This direct transfer method allows for incredible ink density and consistency across millions of impressions. Modern machines are typically designed in a modular "station" format, where each color requires its own dedicated printing unit. This setup allows for complex layering, including specialty coatings, metallic inks, and tactile finishes that other printing methods struggle to replicate with the same level of crispness and depth.

Critical Components and Their Functional Roles

To achieve the micron-level precision required for high-definition packaging, several sophisticated subsystems must work in perfect synchronicity. The reliability of a rotogravure machine is largely dependent on the quality of its tension control and drying systems, which prevent substrate stretching and ink smearing at speeds often exceeding 600 meters per minute.

The Inking and Doctor Blade System

The doctor blade is perhaps the most critical consumable in the machine. It must maintain a precise angle and pressure against the chrome-plated cylinder to ensure a "clean wipe." Any vibration or misalignment here results in streaks or "hazing" on the final product. Advanced machines now utilize enclosed ink chambers to reduce solvent evaporation and maintain consistent ink viscosity throughout the run.

Drying and Exhaust Units

Because rotogravure often uses solvent-based inks for superior adhesion on plastic films, high-capacity drying hoods are positioned between each color station. These units use high-velocity heated air to flash-off solvents instantly. Modern eco-friendly designs often integrate Heat Recovery Systems (HRS) to repurpose the thermal energy, significantly lowering the carbon footprint of the facility.

Performance Comparison: Rotogravure vs. Flexography

Choosing between rotogravure and other printing methods usually comes down to a balance of volume and quality. While the initial cost of engraving gravure cylinders is higher than producing flexo plates, the durability and output quality of gravure often make it more economical for massive production cycles. The following table highlights the key differentiators for manufacturers evaluating these technologies.

| Feature |

Rotogravure Machine |

Flexographic Machine |

| Image Carrier |

Engraved Metal Cylinder |

Photopolymer Plate |

| Print Durability |

Extremely High (Millions of meters) |

Moderate (Plate wear over time) |

| Color Consistency |

Superior throughout the run |

Variable based on plate pressure |

| Ideal Run Length |

Large Scale / High Volume |

Short to Medium Runs |

Advancements in Automation and Sustainability

The latest generation of rotogravure machines focuses on reducing "make-ready" times and material waste. Historically, gravure was criticized for high setup waste, but smart automation has significantly mitigated these issues. Manufacturers are now integrating Industry 4.0 features to ensure the process is as efficient as possible.

- Automatic Register Control: High-speed cameras detect register marks in real-time, automatically adjusting cylinder positions to within 0.1mm accuracy.

- Electronic Line Shaft (ELS) Technology: By replacing mechanical drive shafts with independent servo motors for each station, machines achieve higher synchronization and less mechanical wear.

- Water-Based Ink Compatibility: New drying configurations allow machines to handle water-based inks, reducing VOC emissions and aligning with global sustainability mandates.

- Quick-Change Trolleys: These allow operators to prep the next job’s cylinders and ink pumps offline, reducing downtime between jobs to a matter of minutes rather than hours.

As the demand for premium packaging in the food, beverage, and pharmaceutical sectors continues to grow, the rotogravure machine remains the preferred choice for brands that cannot compromise on visual impact or repeatable precision.