Understanding Rotogravure Machines

Rotogravure machines are high-precision printing systems widely used in large-scale production of packaging materials, decorative films, wallpapers, and labels. They are part of the gravure printing family, where images are engraved onto cylinders, allowing for consistent high-quality printing on a variety of substrates. Their efficiency and flexibility make them indispensable in industries where mass production with detailed designs is required.

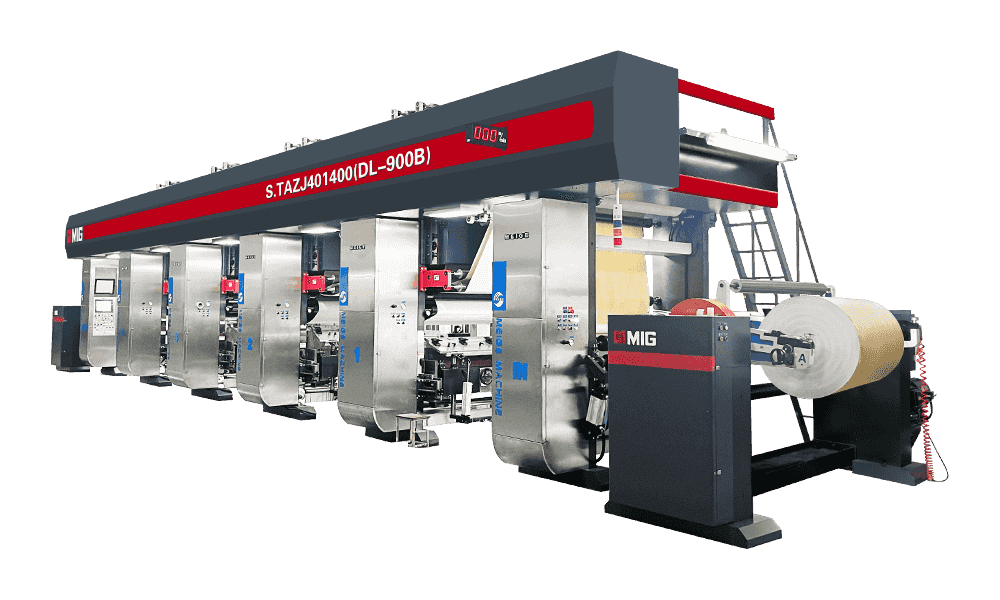

Key Components of a Rotogravure Machine

A rotogravure machine consists of several critical components that work together to deliver precision printing:

- Engraved Cylinders: Steel or copper cylinders engraved with fine patterns, which hold the ink.

- Doctor Blade: Removes excess ink from the cylinder surface, ensuring only engraved cells hold ink for transfer.

- Anilox Rollers: In some systems, used to regulate ink transfer from the reservoir to the cylinder.

- Substrate Feeding System: Guides flexible substrates like plastic film, paper, or aluminum foil through the machine.

- Drying Units: Hot air or infrared systems to dry the ink immediately after printing.

- Rewinding Unit: Collects printed material in rolls for further processing or finishing.

How Rotogravure Printing Works

Rotogravure printing is a combination of precision engineering and fluid dynamics. Ink is applied to the engraved cells of a cylinder. The doctor blade wipes off excess ink from the surface, leaving ink only in the engraved portions. When the substrate passes between the cylinder and an impression roller, the ink is transferred onto the material. This method allows for high-speed printing with fine detail and uniform color distribution.

Printing Process Details

The gravure printing process involves multiple steps to ensure consistent quality:

- Preparation of cylinders using laser engraving or chemical etching.

- Careful selection of ink based on substrate type and desired finish.

- Calibration of doctor blades to control ink film thickness.

- Speed synchronization between cylinder rotation and substrate feed.

- Drying and curing of ink to prevent smudging and ensure durability.

Applications of Rotogravure Machines

Rotogravure machines are versatile and used across various industries for both decorative and functional printing:

- Flexible packaging for food products, pharmaceuticals, and consumer goods.

- Decorative films and laminates for furniture, flooring, and automotive interiors.

- Wallpaper and gift wrap printing with complex patterns and multiple colors.

- Security printing for stamps, certificates, and high-value labels.

Advantages of Using Rotogravure Machines

The technology offers numerous benefits over other printing methods, making it a preferred choice for large-scale production:

- High-Speed Production: Capable of printing thousands of meters per hour.

- Consistent High Quality: Fine details and gradients can be reproduced accurately.

- Flexibility: Works on various materials including plastic films, foils, and paper.

- Durability: Engraved cylinders are long-lasting, ideal for repeated runs.

Maintenance and Operational Tips

Proper maintenance is crucial to ensure the longevity and efficiency of a rotogravure machine. Key practices include:

- Regular cleaning of cylinders and doctor blades to prevent ink build-up.

- Periodic inspection of rollers, bearings, and substrate guides for wear and tear.

- Monitoring ink viscosity and drying conditions for optimal transfer.

- Keeping precise alignment between all machine components to avoid print defects.

Comparing Rotogravure to Other Printing Techniques

While several printing technologies exist, rotogravure stands out for specific applications. The following table summarizes key differences:

| Feature |

Rotogravure |

Flexography |

Offset Printing |

| Speed |

Very High |

High |

Medium |

| Detail Reproduction |

Excellent |

Good |

Very Good |

| Substrate Variety |

Wide |

Medium |

Limited |

| Cost for Large Runs |

Low per unit |

Moderate |

High per unit |

Future Trends in Rotogravure Technology

Rotogravure printing is evolving with digital integration and automation. Emerging trends include:

- Smart sensors for real-time quality monitoring and defect detection.

- Eco-friendly inks and water-based solutions to reduce environmental impact.

- Automation in cylinder engraving to shorten production lead times.

- Integration with Industry 4.0 systems for predictive maintenance and process optimization.

Conclusion

Rotogravure machines remain a cornerstone of high-quality printing across packaging, decorative, and security industries. Their unmatched precision, speed, and flexibility make them ideal for mass production, while ongoing technological advancements continue to enhance efficiency and sustainability. For businesses seeking consistent and premium printing output, investing in modern rotogravure technology is a strategic decision that delivers both quality and scalability.