Revolutionizing Packaging: The Ultimate Guide to Rotogravure Printing Machines

Understanding Rotogravure Printing Technology

Rotogravure printing is a high-speed, high-quality printing process widely used in packaging, labels, and decorative printing industries. Unlike traditional printing methods, rotogravure uses engraved cylinders to transfer ink onto substrates, ensuring precise reproduction of fine details, gradients, and images. Its ability to handle large-scale production with consistent quality makes it a preferred choice for manufacturers of flexible packaging, magazines, and laminates.

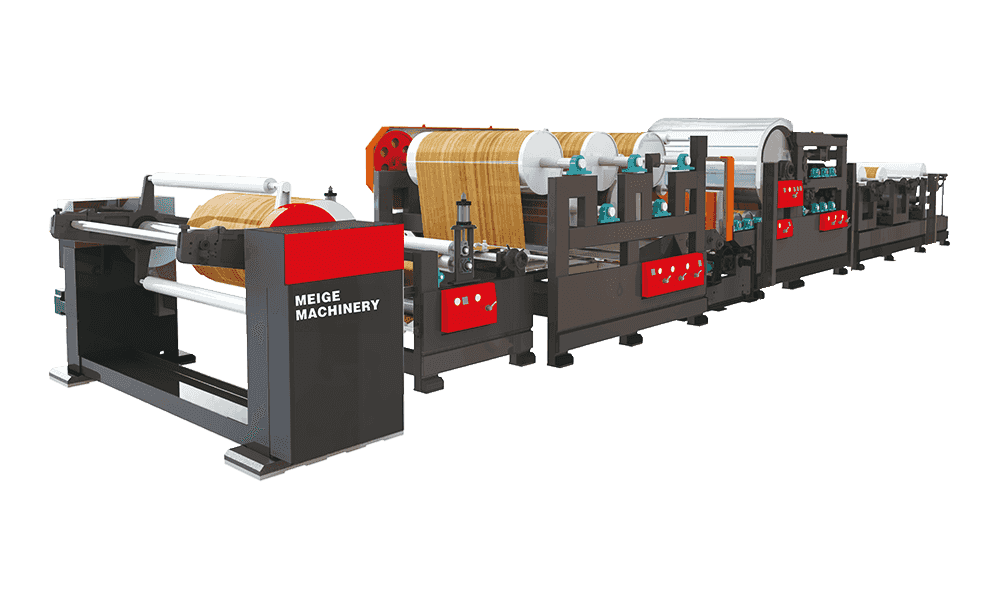

Core Components of a Rotogravure Printing Machine

A rotogravure printing machine consists of several critical components that work in unison to deliver exceptional print quality:

- Gravure Cylinder: Engraved with tiny cells, it holds the ink that will be transferred to the substrate.

- Anilox or Doctor Blade: Removes excess ink from the cylinder, ensuring precise ink transfer and consistent color density.

- Impression Roller: Presses the substrate against the gravure cylinder, ensuring uniform contact and transfer of ink.

- Ink System: Maintains proper viscosity and circulation of inks suitable for various materials like plastics, foils, or paper.

- Drying System: Quickly dries the ink using hot air, infrared, or UV systems to maintain production speed.

Applications of Rotogravure Printing Machines

Rotogravure machines are widely used across industries due to their flexibility, precision, and high-speed capabilities. Key applications include:

- Flexible Packaging: Printing on films like BOPP, PET, and laminated materials for food, pharmaceuticals, and consumer goods.

- Magazine and Catalog Printing: Delivering high-resolution images and consistent color for mass circulation publications.

- Decorative Laminates: Producing patterns for furniture, wallpapers, and decorative films with detailed textures and colors.

- Labels and Tags: High-quality product labeling with sharp images, barcodes, and vibrant color reproduction.

Advantages of Using Rotogravure Printing Machines

The rotogravure printing process offers several benefits that make it a popular choice for commercial printing and packaging solutions:

- High-Speed Production: Capable of printing thousands of meters per hour, ideal for large-scale manufacturing.

- Superior Print Quality: Excellent image clarity and color consistency, even on textured surfaces or uneven substrates.

- Versatile Material Compatibility: Can print on a wide range of substrates including plastic, foil, paper, and laminates.

- Long-Run Efficiency: Engraved cylinders are durable, allowing for extended production runs with minimal downtime.

Maintenance and Operational Tips

To maintain optimal performance and longevity of a rotogravure printing machine, consider the following operational practices:

- Regular Cylinder Cleaning: Prevents ink residue buildup that can affect print quality and consistency.

- Doctor Blade Adjustment: Ensure proper blade pressure to avoid scratches and uneven ink transfer.

- Ink Viscosity Monitoring: Maintain stable ink flow and prevent drying or clumping inside the system.

- Lubrication and Machine Checks: Regularly check rollers, bearings, and gears to reduce wear and tear.

Future Trends in Rotogravure Printing

The rotogravure printing industry is evolving rapidly with advancements in technology. Key trends shaping the future include:

- Integration of Digital Controls: Enhancing precision, monitoring, and automation for faster and more efficient production.

- Environmentally Friendly Inks: Increasing use of water-based and UV-cured inks to reduce environmental impact.

- Hybrid Printing Systems: Combining rotogravure with flexographic or digital printing for versatile, short-run, and customizable packaging.

- Smart Maintenance: Predictive analytics and IoT-enabled sensors to monitor performance and reduce machine downtime.