Technical Core of Gravure Printing for Decorative Paper

Gravure printing remains the gold standard for producing decorative paper used in engineered wood products like laminate flooring, furniture panels, and wall coverings. This process utilizes an engraved cylinder that carries ink within recessed cells, transferring high-definition wood grain or stone patterns onto specialized base paper. The machinery must maintain extreme precision to ensure that the visual texture—often mimicking natural oak, walnut, or marble—remains consistent across thousands of meters of production. High-speed operation combined with precise tension control is essential to prevent the delicate base paper from stretching, which would otherwise distort the pattern repeat.

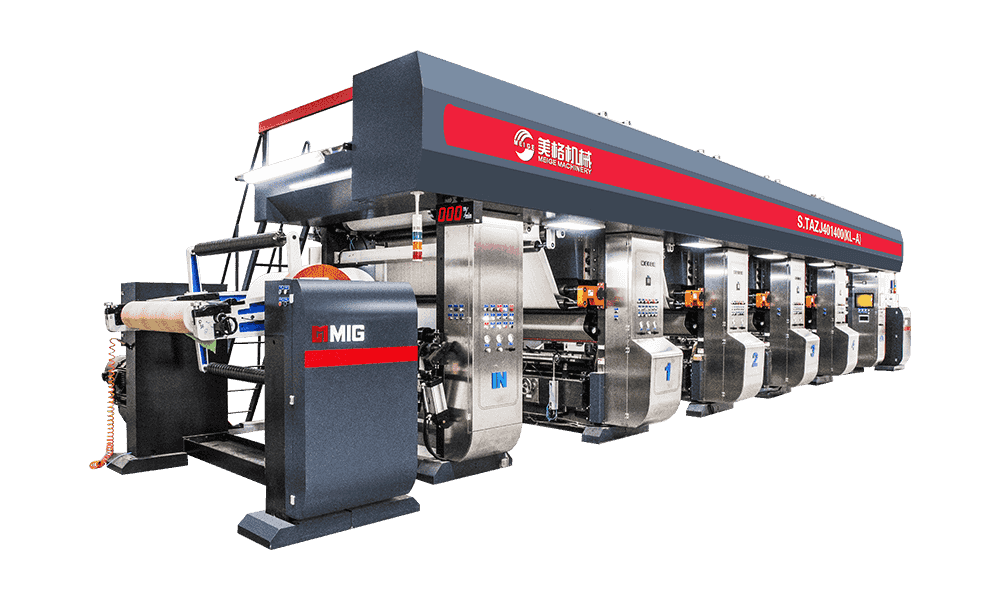

Key Components of an Industrial Gravure Press

- Unwinding Station: Features automatic splicing systems to ensure continuous production without stopping for roll changes.

- Printing Units: Equipped with doctor blade assemblies that precisely wipe excess ink from the cylinder surface.

- Drying Tunnels: High-efficiency hot air systems that quickly evaporate solvents or water-based inks before the next color is applied.

- Automatic Register Control: Uses optical sensors to align multiple colors within microns of accuracy.

Precision Registration and Multi-Color Overlay

In the production of decorative paper for engineered wood, achieving a realistic "3D" effect requires multiple color overlays, typically ranging from three to five colors. Each color unit in the gravure machine must be perfectly synchronized. Modern machines utilize electronic line shafts (ELS) where each printing cylinder is driven by an independent servo motor. This eliminates the mechanical play found in traditional gear-driven systems, allowing for faster setup times and significantly reduced paper waste during the "make-ready" phase. The ability to maintain registration at speeds exceeding 200 meters per minute is what separates industrial-grade equipment from entry-level alternatives.

Technical Specifications Comparison for Decorative Paper Machines

| Feature |

Standard Gravure Press |

High-End Decorative Press |

| Max Printing Width |

1000mm - 1300mm |

1300mm - 2300mm |

| Registration Accuracy |

± 0.15mm |

± 0.05mm |

| Drying Method |

Electric/Steam |

Thermal Oil / Intelligent Air Recirculation |

| Drive System |

Mechanical Shaft |

Electronic Line Shaft (ELS) |

Ink Management and Environmental Considerations

The decorative paper industry is increasingly shifting toward water-based inks to meet stringent VOC (Volatile Organic Compound) emission standards. Gravure printing machines designed for engineered wood must be equipped with specialized ink circulation systems that prevent sedimentation and maintain constant viscosity. Advanced machines feature stainless steel ink pans and ceramic-coated rollers to resist corrosion from water-based chemistries. Furthermore, integrated viscosity controllers automatically add solvent or water to the ink fountain, ensuring that the color density remains identical from the start of the print run to the very end.

Advantages of Modern Ink Systems

- Improved lightfastness to prevent furniture fading over time.

- Enhanced resin absorption during the subsequent melamine impregnation process.

- Reduced environmental footprint and safer workplace conditions for operators.

Optimizing Tension Control for Large Format Printing

Engineered wood decorative paper is often printed on wide formats to accommodate large particleboard or MDF panels. Managing web tension across a 2100mm wide roll of paper requires sophisticated closed-loop control systems. Using dancer rollers and load cells, the machine's PLC (Programmable Logic Controller) calculates the exact torque required at the rewinder and unwinder. This prevents "telescoping" of the paper rolls and ensures that the paper is wound with uniform density. Proper tension management is the primary factor in reducing wrinkles and ensuring the paper behaves predictably when it eventually enters the melamine resin bath.