The Role of Gravure Technology in Wood Grain Reproduction

Gravure printing stands as the industry standard for producing high-quality decorative paper used in the engineered wood sector, including laminate flooring, furniture panels, and wall coverings. The process relies on an intaglio printing method where the image is etched into a metal cylinder. This allows for an incredibly high ink load and fine detail, which is essential for mimicking the organic complexity of natural wood grains, marble textures, and tactile finishes. For engineered wood products, the precision of the gravure machine determines the depth and realism of the final aesthetic, making it a critical asset for manufacturers aiming for premium market positioning.

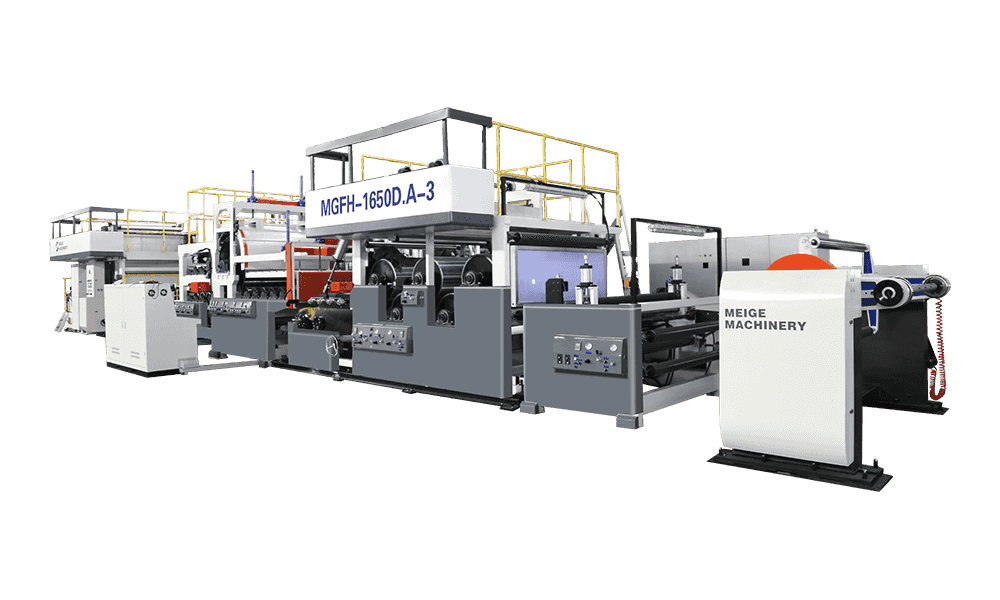

Unlike digital or offset printing, Gravure Printing Machine for Engineered Wood Decorative Paper are built for high-speed, continuous production on wide webs. The ability to maintain color consistency across thousands of meters is what sets this technology apart. In the context of engineered wood, where panels must match perfectly during installation, the mechanical stability and ink viscosity control of a gravure press are non-negotiable features for quality assurance.

Core Components and Mechanical Precision

Advanced Inking Systems and Doctor Blade Assembly

The heart of the gravure machine lies in its inking system. For decorative paper, water-based inks are predominantly used to meet environmental standards and ensure compatibility with subsequent resin impregnation processes. A high-precision doctor blade is employed to wipe excess ink from the non-engraved areas of the cylinder. Modern machines utilize "chambered" doctor blades or pneumatic pressure systems to ensure that the wiping pressure remains constant even as the machine accelerates, preventing streaks or "fogging" on the delicate paper substrate.

High-Efficiency Drying Tunnels

Because decorative paper for engineered wood is often printed in multiple layers (base color, grain pattern, and highlights), the drying capacity of the machine is vital. Each printing station is followed by a drying tunnel that uses high-velocity hot air or infrared heat. Effective drying ensures that the ink is fully "set" before the paper reaches the next station, preventing smudging or color bleeding. This is particularly important when printing on thin, absorbent base papers that are sensitive to moisture-induced expansion.

Technical Specifications for Decorative Paper Production

When selecting or configuring a gravure printing machine for the decorative paper industry, several technical parameters must be optimized to handle the specific weight and porosity of the substrate. The table below outlines the standard requirements for a professional-grade setup:

| Parameter |

Standard Requirement |

| Printing Speed |

150 - 300 meters per minute |

| Substrate Weight |

30 - 120 g/m² (Decorative Base Paper) |

| Register Accuracy |

≤ ±0.1 mm (Vertical and Horizontal) |

| Cylinder Diameter |

150 mm - 450 mm (Pattern Dependent) |

| Tension Control |

Closed-loop Automatic Control |

Operational Best Practices for High-Quality Output

To achieve the "engineered wood" look that customers demand, operators must manage several variables simultaneously. Success in gravure printing is as much about chemistry and physics as it is about machinery. Key operational focus areas include:

- Tension Management: Decorative paper is prone to stretching or wrinkling. Automated tension control systems at the unwind and rewind stages are essential to prevent pattern distortion.

- Viscosity Control: Consistent ink viscosity is the only way to ensure color uniformity. Integrated viscosity controllers automatically add solvent or water to maintain the desired flow rate.

- Cylinder Maintenance: Chrome-plated cylinders must be inspected for wear. Even minor scratches can result in repetitive defects that ruin an entire batch of decorative paper.

- Environment Regulation: Keeping the print room at a stable temperature and humidity level prevents the paper from curling and ensures the ink dries at a predictable rate.

Future Trends in Engineered Wood Printing

The industry is currently moving toward "Synchronized Grain" or Embossed-in-Register (EIR) technology. This requires the gravure printing machine to work in perfect harmony with the downstream pressing and lamination lines. High-resolution optical sensors are now being integrated into gravure presses to print "tracking marks" that digital cameras on the press lines use to align the physical texture of the laminate with the printed wood grain.

Additionally, the shift toward sustainability is driving the development of more efficient gravure machines that reduce ink waste and utilize energy-recovery systems in the drying tunnels. As the demand for realistic, durable, and eco-friendly engineered wood grows, the sophistication of the gravure printing machine remains the cornerstone of the decorative surface industry.