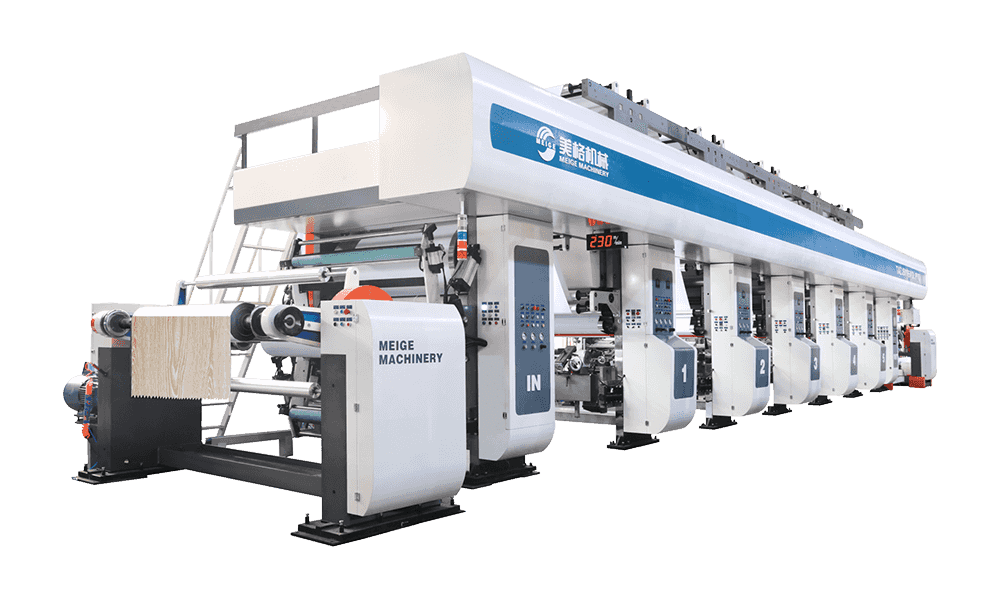

Core Mechanics of High-Speed PVC Gravure Printing

High-speed PVC gravure printing operates on the principle of direct transfer, where an engraved cylinder rotates in an ink fountain to pick up pigment. As the PVC substrate passes between the plate cylinder and the impression roller, the ink is transferred from the recessed cells of the cylinder onto the material. Modern high-speed machines are engineered to handle the specific surface tension and elasticity of PVC, ensuring that the ink adheres perfectly without smudging, even at speeds exceeding 200 meters per minute. This precision is vital for maintaining the aesthetic integrity of products like decorative films, flooring, and synthetic leather.

Advanced Tension Control Systems

Because PVC is sensitive to heat and stretching, high-speed printers utilize sophisticated multi-stage tension control systems. These systems use ultrasonic sensors and dancers to monitor the web tension in real-time, preventing the material from deforming. By maintaining a constant tension throughout the unwinding, printing, and rewinding phases, the machine ensures that multi-color patterns remain perfectly aligned, a process known as registration. Without this level of control, the "creep" in PVC material would result in blurry images and significant material waste.

Technical Specifications and Performance Metrics

When evaluating a high-speed PVC gravure printer, the technical configuration determines the machine's versatility and long-term ROI. Most industrial-grade units feature independent motor drives for each printing station, allowing for faster setup and reduced mechanical vibration. The table below outlines the standard performance parameters found in top-tier PVC printing equipment:

| Feature |

Standard Specification |

| Printing Speed |

150 - 300 m/min |

| Substrate Thickness |

0.03mm - 0.25mm |

| Registration Accuracy |

±0.1mm (Vertical/Horizontal) |

| Drying Method |

Dual-path Hot Air / IR Heating |

Critical Drying and Cooling Requirements for PVC

Drying is perhaps the most challenging aspect of high-speed PVC printing. Unlike paper, PVC cannot absorb ink, so the solvent must be evaporated quickly using high-velocity air nozzles. However, excessive heat can cause the PVC to shrink or warp. Therefore, modern printers use a "low temperature, high volume" airflow strategy. Following the drying tunnel, the substrate must be immediately passed over water-cooled rollers to bring the material back to room temperature, setting the ink and stabilizing the plastic before it is wound onto the final roll.

Operational Best Practices for High-Volume Production

To maintain peak performance and extend the lifespan of the engraving cylinders, operators should adhere to strict maintenance and calibration protocols. High-speed environments leave little room for error, as even a small misalignment can result in hundreds of meters of ruined substrate within minutes.

- Regularly check the angle and pressure of the doctor blade to ensure clean ink wiping and prevent cylinder wear.

- Monitor ink viscosity continuously; high speeds require lower viscosity to ensure the cells fill and empty correctly.

- Utilize stroboscopic inspection lights or digital camera systems to monitor print quality without slowing down the machine.

- Ensure the static elimination bars are functional, as PVC generates significant static electricity at high speeds, which can cause fire hazards or "spiderwebbing" in the ink.

Future Trends in PVC Gravure Printing

The industry is currently shifting toward more sustainable practices, including the adoption of water-based inks and energy-efficient LED drying systems. While traditional solvent-based inks offer superior adhesion on PVC, advancements in surface treatment technology, such as inline Corona treaters, are making it possible for high-speed gravure printers to utilize eco-friendly alternatives. Additionally, the integration of Industry 4.0 IoT sensors allows plant managers to track real-time power consumption and predictive maintenance needs, further reducing downtime in high-demand production environments.