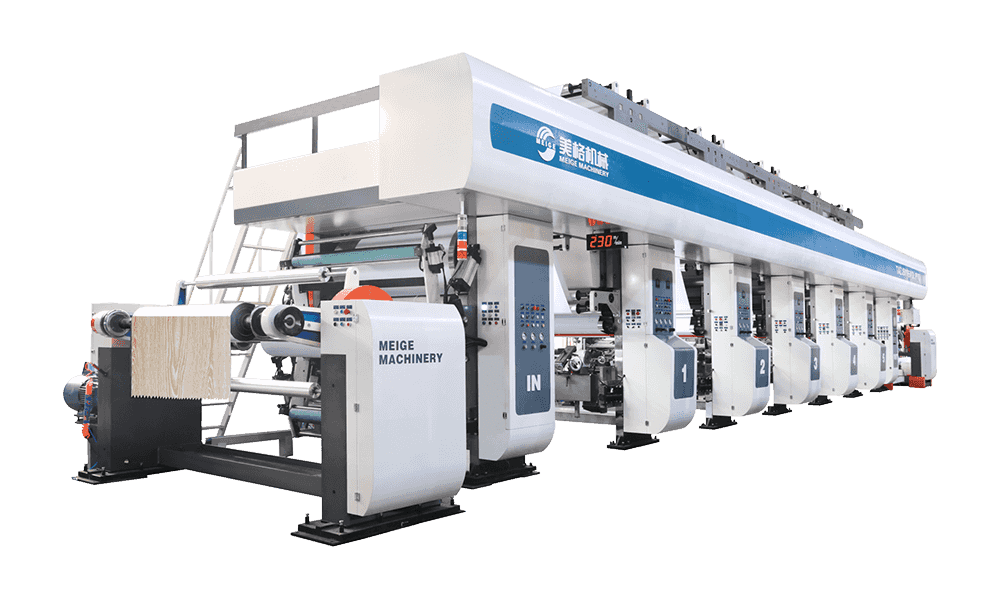

Advanced Drive Systems in High-Speed PVC Gravure Printing

The performance of a high-speed PVC gravure printer is fundamentally defined by its drive and control architecture. Modern machines utilize an electronic shaft (ELS) system or a high-precision mechanical linkage combined with AC servo motors. These systems allow the printer to reach speeds exceeding 250-300 meters per minute while maintaining razor-sharp registration. On PVC substrates, which are sensitive to temperature and tension, the drive system must compensate for the material's inherent elasticity to prevent ghosting or misalignment of the pattern.

Tension Control and Web Stability

Maintaining constant tension is critical when handling PVC films. High-speed printers employ a four-section closed-loop tension control system comprising the unwinder, the in-feed traction, the out-feed traction, and the rewinder. By using low-friction dancing rollers and high-resolution load cells, the machine can detect even the slightest fluctuation in web tension and adjust motor speeds in real-time, ensuring the PVC film does not stretch or wrinkle during high-velocity passes.

Technical Specifications of Industrial PVC Gravure Machines

To achieve industrial-grade output, certain hardware configurations are non-negotiable. The following table outlines the standard technical parameters found in top-tier high-speed PVC gravure printing equipment:

| Feature |

Specification Detail |

| Max Printing Speed |

200 - 350 m/min |

| Applicable Materials |

PVC, PET, BOPP, PE, Paper |

| Registration Accuracy |

± 0.1mm (Vertical & Horizontal) |

| Drying Method |

High-efficiency Intelligent Hot Air System |

| Doctor Blade Type |

Pneumatic Heavy-Duty Blade with 3-Way Adjustment |

Ink Transfer and Drying Efficiency on PVC Substrates

PVC is a non-porous material, meaning ink must dry rapidly on the surface without penetrating the substrate. High-speed gravure printers utilize specialized drying hoods equipped with dual-directional airflow. This setup ensures that high volumes of solvent-based or water-based inks are evaporated quickly enough to support high-velocity rewinding without smudging or "blocking" (ink sticking to the back of the film).

Optimized Doctor Blade Assemblies

The doctor blade's role is to wipe excess ink from the non-image areas of the gravure cylinder. In high-speed operations, friction generates significant heat. Modern PVC printers use heavy-duty, pneumatic doctor blades with oscillating movements to reduce wear on the cylinder and ensure a consistent ink film thickness, which is vital for maintaining color density across thousands of meters of film.

Operational Advantages of Modern High-Speed Systems

Investing in high-speed gravure technology provides manufacturers with a distinct competitive edge in the flexible packaging and decorative film markets. The integration of automation reduces manual intervention and minimizes material waste during job changeovers.

- Automatic Splicing: Continuous operation is achieved through turret-style unwinding and rewinding units that swap rolls at full production speed.

- Vision Inspection: High-resolution cameras detect printing defects, color deviations, or register errors instantly, alerting operators to issues before they become costly.

- Energy Recovery: Modern drying tunnels often include heat recirculation systems to lower the overall electrical consumption of the plant.

- Static Elimination: Integrated static bars neutralize the PVC web, preventing fire hazards from solvent inks and ensuring smooth winding.

Maintenance Protocols for Longevity and Precision

To sustain the precision of a high-speed PVC gravure printer, a rigorous maintenance schedule is required. This involves the systematic inspection of the impression rollers to ensure no hardening or pitting has occurred, as well as the calibration of the spectrophotometers used for in-line color management. Regular cleaning of the ink circulation system prevents dried pigment buildup, which can cause "streaking" or damage the expensive engraved cylinders. Furthermore, checking the alignment of the guide rollers prevents "tracking" issues that lead to lateral registration drift during high-speed runs.