Industry knowledge

What are the most important factors to consider when selecting a waste paper baler for a specific application?

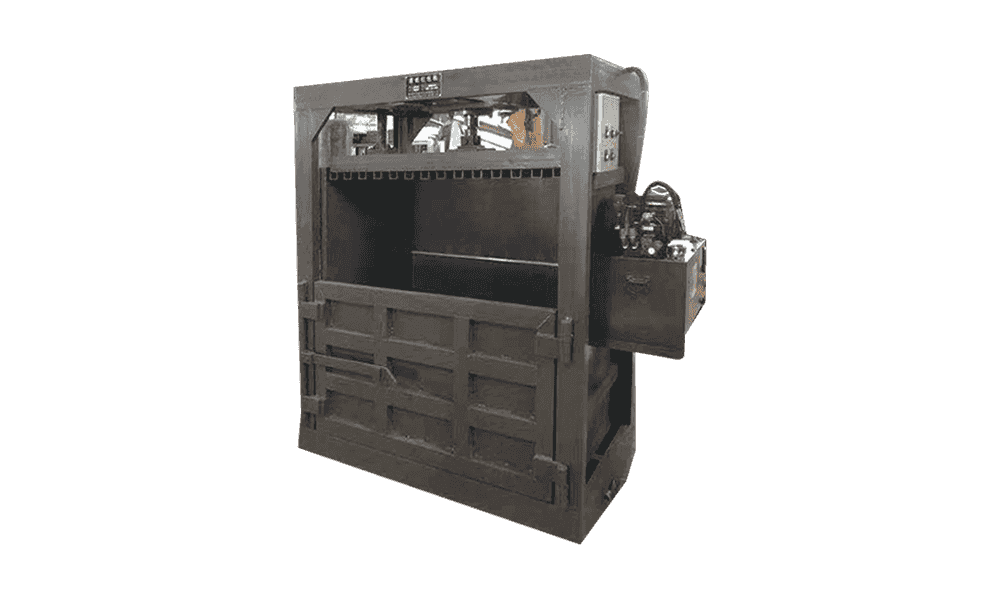

A waste paper baler is a vital piece of equipment for any business that generates significant paper waste, including those in the printing industry where materials like paper, cardboard, and film are abundant. Zhejiang Meige Machinery Co., Ltd., a national high-tech enterprise specializing in gravure printing machines, would find a waste paper baler a crucial component of a comprehensive and efficient waste management strategy.

The Most Important Factors in Selecting a Baler

Selecting the right waste paper baler is a decision that requires careful thought. Here are the most critical factors to consider:

-

Waste Volume and Type: This is the most important factor. The sheer volume of waste generated by a company, especially a large-scale printing operation like those served by Zhejiang Meige Machinery, dictates the type of baler needed. A high volume of cardboard and paper requires a heavy-duty, industrial-grade baler. The type of waste—be it office paper, cardboard, or plastic film—also influences the baler's design and features. As a company that produces pre-press and post-press supporting equipment, Meige Machinery understands the diverse waste streams of its customers.

-

Operational Efficiency and Automation: For businesses like the ones Meige Machinery serves, which are focused on high-speed and automated processes, a baler with similar characteristics is essential. Features like automatic tying and continuous feeding can significantly reduce labor costs and increase efficiency. As a company that guides its development through technological innovation and the launch of high-performance, intelligent products, Meige Machinery would likely prioritize these automated features when either using a baler for its own operations or recommending one to its clients.

-

Bale Size and Density: The size and weight of the compacted bales are important for both handling and transportation. They need to be a manageable size for your team to move and should meet the specific requirements of the recycling facility. A denser bale also means you can fit more material into a single shipment, reducing transportation costs. Meige Machinery's focus on high-quality development projects and improving efficiency would align with the need for a baler that produces dense, uniform bales for maximum value and cost savings.

-

Space and Location: The physical footprint of the baler is another key consideration. Vertical balers are space-savers, ideal for businesses with limited floor space, while horizontal balers require more room but are more efficient for high-volume operations. Meige Machinery, with its 45,000 square meter workshop, likely has the space to accommodate a larger, more efficient horizontal baler to handle the waste from its manufacturing processes.

-

Safety and Maintenance: Given Meige Machinery's commitment to quality, environment, and occupational health management systems, a baler with robust safety features is non-negotiable. Essential safety features include emergency stop buttons, safety guards, and interlocks. Furthermore, a durable machine with a good warranty and reliable service, which Meige Machinery provides for its own products, would be a critical factor in a purchase decision, ensuring minimal downtime and a longer lifespan for the equipment.

How a Sample Dipping Machine Works

A sample dipping machine works by automating the process of immersing a sample into a liquid. The fundamental process involves these key steps:

-

Holding the Sample: The machine's sample holder—which can be a robotic arm, clamp, or conveyor system—secures the item. This ensures the sample is held stable and in the correct position.

-

Controlled Immersion: The machine uses a controlled mechanism, such as a pulling wire or lead-screw drive, to lower the sample into a tank of liquid. The machine precisely controls key variables like the speed of immersion, the dipping time, and the depth of the dip to ensure a uniform result.

-

The Dipping Process: Once lowered, the sample remains submerged for a programmed duration. In some advanced systems, a second mechanism might gently press the sample to ensure full submersion and a consistent coating.

-

Controlled Retrieval: The machine then lifts the sample out of the liquid at a controlled speed. This is a critical step for achieving a uniform coating thickness without drips or uneven marks. After retrieval, the sample might be moved to a drying or curing stage, which can be part of the machine's automated cycle.

The primary advantage of using a sample dipping machine is the elimination of human error. This automation ensures that every sample is treated identically, which is crucial for achieving repeatable results in quality control and scientific research.

English

English 中文简体

中文简体