Industry knowledge

What are the main advantages of using an electric forklift compared to a gas-powered one?

Cost-Effectiveness & Sustainability

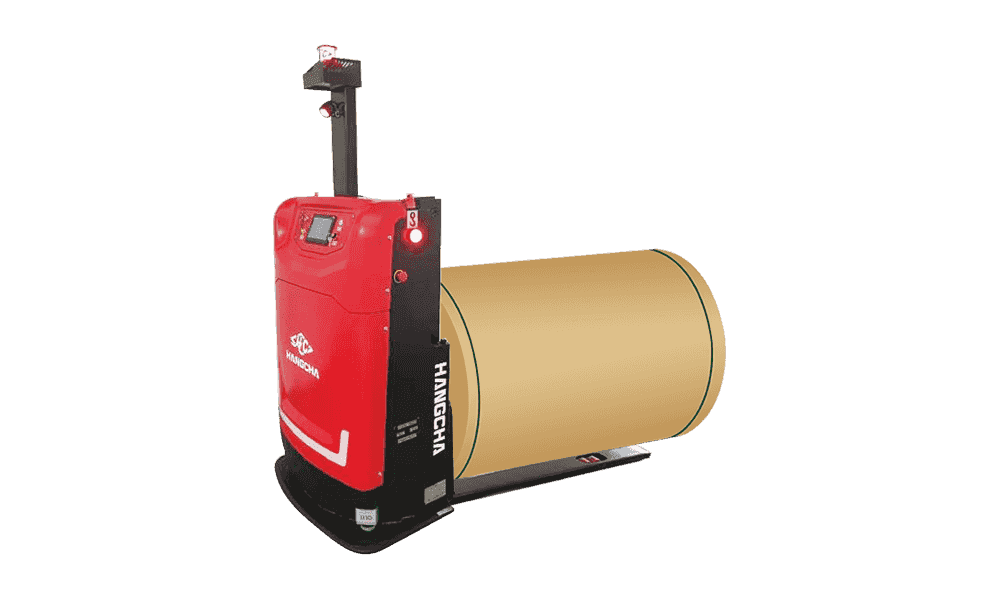

One of the primary advantages of an electric forklift is its lower long-term cost. While the initial purchase price might be higher, you'll save a lot on operating and maintenance expenses. Electricity is generally more affordable and stable in price than gasoline or propane, and electric models require far less maintenance due to having fewer moving parts. This eliminates the need for frequent oil changes, filter replacements, and other costly engine upkeep. Additionally, electric forklifts produce zero emissions, making them a sustainable choice that improves indoor air quality and worker safety by eliminating harmful exhaust fumes.

Enhanced Performance & Safety

Electric forklifts are quieter and more maneuverable than their gas-powered counterparts. Their silent operation reduces noise pollution, leading to a more comfortable and less fatiguing work environment. They also have a smaller turning radius, allowing them to navigate tight spaces and narrow aisles with ease. The consistent power output from the battery ensures reliable performance throughout the work shift, unlike gas forklifts that may lose power as the fuel tank empties. The absence of a large propane tank at the rear also improves the operator's rearward visibility, enhancing overall safety.

WWhat is a plate rolling machine and how does it differ from other metal-bending equipment?

What Is a Plate Rolling Machine?

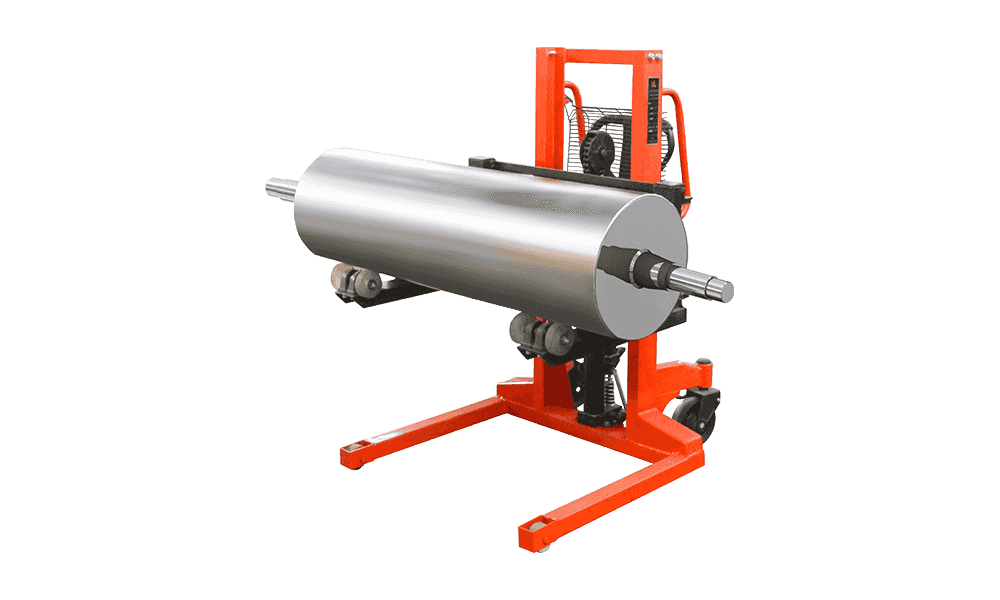

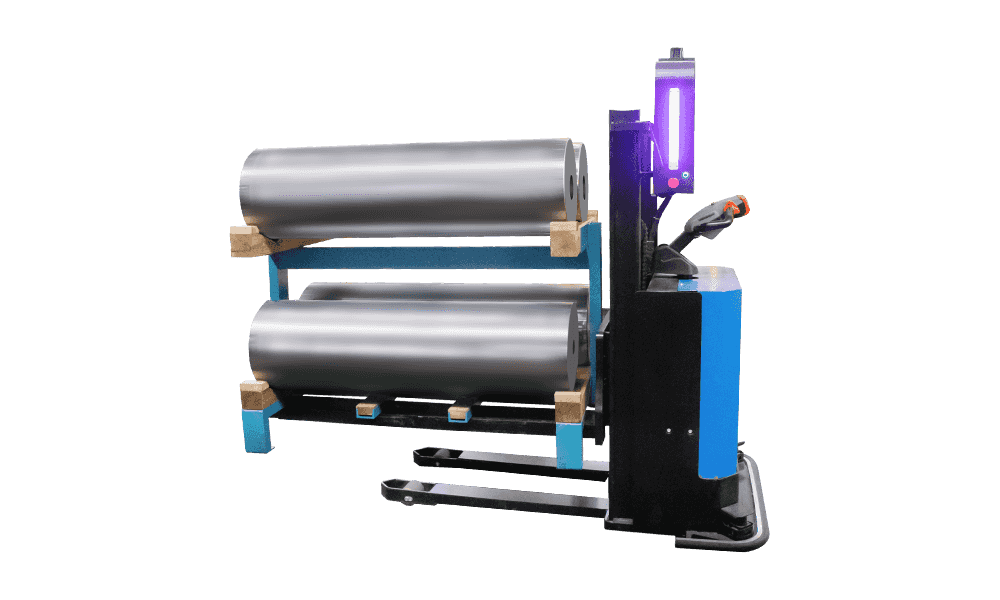

A plate rolling machine, also known as a roll bending machine or plate bender, is a specialized piece of industrial equipment used to bend metal sheets into curved shapes. The core principle behind its operation is often referred to as "three points make a circle." By adjusting the relative positions of its three or four work rollers, the machine applies continuous pressure and bending force to a flat metal sheet, causing it to deform plastically and form a cylinder, cone, arc, or other curved profile.

Types and Working Principles

Plate rolling machines are primarily categorized into two types based on their roller configuration: three-roll and four-roll. A three-roll machine is the more common and simpler type, but it often requires multiple passes to pre-bend the edges of the plate. The more advanced four-roll machine securely clamps the plate between its top and bottom rollers and uses two side rollers to complete both the pre-bending and final rolling in a single pass. This makes the four-roll machine more efficient and ideal for projects that require high precision.

Applications

Plate Roller Truck are crucial in a wide range of modern industries. In the energy and chemical sectors, they are used to fabricate pressure vessels, storage tanks, and pipes. In construction and civil engineering, they produce large steel structural components and bridge parts. For transportation, they are essential for manufacturing ship hulls, as well as airplane and automotive components. Additionally, they are frequently used to create wind turbine towers, ventilation ducts, and various decorative metal products.

How to Choose the Right Machine

When selecting a plate rolling machine, it's critical to consider your specific needs. First, you must determine the required material thickness and width, as well as the minimum rolling diameter for your projects. Next, consider the types of products you'll be making. If you need to roll cones or other complex shapes, a machine with a Computer Numerical Control (CNC) system is a better option. Finally, base your investment on your production volume and need for automation. For high-volume, repetitive tasks, a more automated four-roll machine can significantly increase efficiency and reduce labor costs.

English

English 中文简体

中文简体