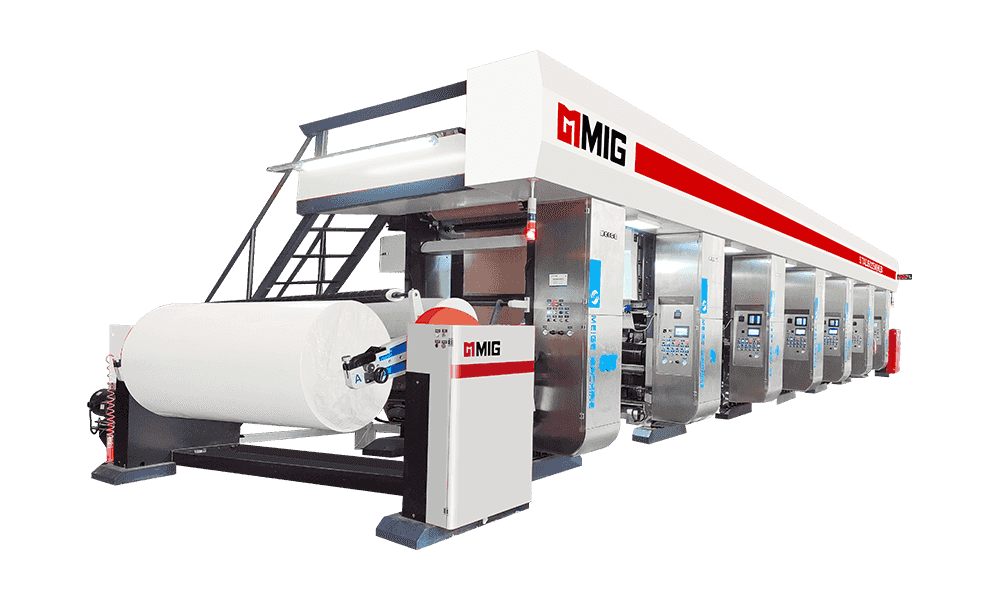

Gravure printing is a high-quality printing process known for its ability to produce rich, vibrant images, often used for magazines, catalogs, and flexible packaging. The machine that makes this possible, a gravure printing press, is a complex piece of equipment with many intricate parts working in concert. Understanding the key components is crucial for anyone involved in the printing industry, from machine operators to engineers.

The Printing Unit: Core of the Gravure Press

The heart of any intaglio printing machine is its printing unit. This is where the actual image transfer occurs. Each unit is typically responsible for one color of ink.

-

Engraved Cylinder: This is the most critical component. The image to be printed is etched (or engraved) onto the surface of a steel cylinder, which is then typically chrome-plated for durability. The microscopic cells of varying depth hold the ink that will be transferred to the substrate.

-

Ink Fountain: This is the reservoir that holds the gravure ink. The cylinder rotates through this fountain, picking up ink that fills the engraved cells.

-

Doctor Blade: As the cylinder rotates, the doctor blade scrapes away excess ink from the non-image areas, leaving only the ink within the cells. The precision of the doctor blade is paramount for print quality, as it directly affects the amount of ink transferred and thus the density of the final print.

-

Impression Roller: This is a rubber-covered roller that presses the substrate (the material being printed on) against the engraved cylinder. The pressure from this roller forces the substrate into the cells, picking up the ink and creating the printed image. The impression roller is often pneumatically or hydraulically controlled to ensure even and consistent pressure.

Web Handling and Registration

For continuous roll-to-roll printing, like that used for flexible packaging, the rotogravure machine needs a sophisticated system for handling the material being printed.

-

Unwind Stand: This component holds the large roll (or "web") of unprinted substrate. It includes a tension control system to ensure the material feeds smoothly into the machine.

-

Infeed Unit: Located after the unwind stand, this unit helps stabilize the web and maintain a consistent tension as it enters the printing units.

-

Guide Rollers: A series of rollers guide the web through the machine, ensuring it stays on the correct path.

-

Dancer Rollers: These rollers are part of the tension control system. They move up and down in response to changes in web tension, helping to keep it constant and prevent wrinkles or tears.

-

Register Control System: This is a highly sophisticated electronic system that ensures each color is printed in the exact same position relative to the others. Modern systems use sensors to read registration marks on the web and make automatic adjustments to the position of the printing cylinders.

Drying and Finishing

Since gravure inks are solvent-based and applied in a thick layer, a powerful drying system is essential after each color is printed.

-

Drying Tunnel/Hood: Immediately following each printing unit is a drying tunnel where heated air and sometimes infrared or UV light is used to evaporate the solvents from the ink.

-

Exhaust System: A robust exhaust system is necessary to remove the evaporated solvents from the machine, ensuring a safe working environment and preventing fire hazards.

-

Chill Rollers: After drying, the web may pass over chill rollers to cool down before entering the next printing unit or the rewind section.

-

Rewind Stand: After all colors have been printed and dried, the finished product is wound onto a final roll on the rewind stand. This stand also has a tension control system to ensure a tightly wound roll.

Control and Safety Systems

Modern gravure presses are highly automated and include a range of control and safety features.

-

Human-Machine Interface (HMI): This is a touch screen or control panel that allows operators to monitor and control various machine parameters, such as speed, tension, and register.

-

Fault Detection Systems: Sensors and cameras can detect printing defects, mis-registration, or web breaks, automatically stopping the machine and alerting the operator.

-

Emergency Stops: Prominently located buttons that can immediately shut down the machine in an emergency.

-

Guarding and Interlocks: Physical guards prevent access to moving parts, and interlock systems ensure the machine cannot operate if guards are not in place.

In conclusion, a rotogravure printing machine is a marvel of engineering, combining mechanical precision with advanced electronics. Each part, from the engraved cylinder to the sophisticated register control, plays a crucial role in producing the high-quality, high-volume prints that are the hallmark of the gravure process.