The demand for high-quality, durable, and visually appealing decorative finishes on plastic materials, particularly Polyvinyl Chloride (PVC), is consistently high across numerous industries. At the heart of meeting this demand lies the PVC Gravure Printing Machine—a specialized piece of equipment essential for producing vibrant, long-lasting printed patterns on PVC films and sheets.

How Gravure Technology Works

The gravure printing process, from which the machine takes its name, is an intaglio (sunken) technique. Unlike letterpress or offset printing, where the image carrier is raised or flat, the gravure cylinder features microscopic cells or wells of varying depth and size etched into its surface.

-

Inking: The rotating cylinder is immersed in an ink fountain, filling all the etched cells with liquid ink.

-

Doctor Blade: A flexible steel blade, known as the doctor blade, wipes away the excess ink from the non-recessed (non-image) areas of the cylinder surface, leaving ink only in the sunken cells.

-

Transfer: The PVC substrate (film or sheet) is brought into contact with the inked cylinder under pressure, often via a rubber impression roller. The pressure transfers the ink from the cells onto the PVC material.

-

Drying: The printed PVC then passes through a drying unit, usually employing hot air, to rapidly set the solvent-based inks before it moves to the next printing unit or winding station.

This system is particularly effective because the varying depths of the etched cells allow for precise control over the amount of ink transferred, resulting in superior tonal variations, smooth gradients, and sharp, continuous images—ideal for reproducing wood grains, marble effects, textile patterns, and photographic quality prints on PVC.

Key Features of the PVC Gravure Printing Machine

A modern PVC Gravure Printing Machine is engineered for precision, speed, and versatility to handle the specific properties of PVC films and sheets:

-

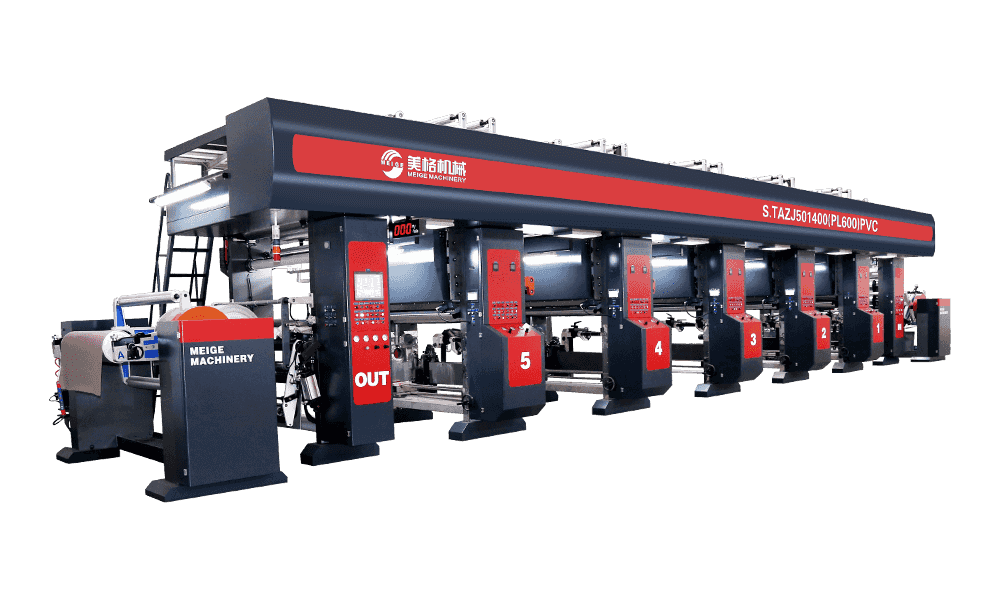

Modular Units: These machines are typically modular, meaning they consist of multiple independent printing stations (color units) in a row. This allows for multi-color printing—each unit applies a single color—to build up complex designs. The number of units determines the maximum number of colors (e.g., an 8-color machine has eight units).

-

Tension Control Systems: PVC is a relatively stretchable substrate. Advanced automatic tension control is crucial to maintain registration accuracy across all color units, ensuring the final image doesn't distort or suffer from misaligned colors.

-

High-Efficiency Drying: Since PVC is heat-sensitive and the inks used are often solvent-based, the drying system must be both highly efficient for rapid production and precisely controllable to prevent damage or shrinkage to the substrate.

-

Substrate Handling: The machine incorporates specialized unwind and rewind systems to handle large rolls of PVC film, often with automatic splice units to allow for continuous, high-speed operation without stopping for roll changes.

-

Register Control: Sophisticated electronic automatic register control systems continuously monitor the alignment of the print from one unit to the next, making minute adjustments in real-time to maintain perfect color overlap.

Applications in Industry

The versatility and durability of prints produced by a PVC Gravure Printing Machine make it indispensable for numerous applications:

-

Flooring: Printing wood-grain or stone-look decorative layers for PVC and vinyl flooring.

-

Furniture & Construction: Producing decorative foils for lamination onto particleboard, MDF (Medium-Density Fiberboard), and wall panels, simulating natural materials or unique textures.

-

Packaging: Creating high-quality, complex graphic prints on flexible PVC packaging films.

-

Automotive: Manufacturing decorative interior trims and surfaces.

In essence, the PVC Gravure Printing Machine is the technology that enables the transformation of a simple polymer sheet into a highly valuable, durable, and aesthetically finished product.