In today's competitive market, efficiency and quality are paramount. A PVC laminating machine offers significant advantages that go beyond the simple application of a film. It is a strategic investment for manufacturers seeking to improve their product offerings while controlling costs and enhancing operational efficiency. The functional benefits of the lamination process itself are numerous, but the economic and long-term advantages of owning a high-quality machine are equally compelling.

Unlocking Cost-Effectiveness and Design Flexibility

One of the most significant advantages of using a PVC laminating machine is its ability to produce high-quality, aesthetically pleasing products at a fraction of the cost of using solid materials. For example, a furniture manufacturer can achieve the look and feel of exotic hardwoods by laminating an MDF board with a realistic wood-grain PVC film. This not only makes the final product more affordable for the consumer but also makes it more accessible to a wider market. The lightweight nature of the laminated substrate also reduces transportation costs. The design flexibility is another key benefit. Manufacturers are not limited to the natural appearance of materials; they can choose from an almost infinite range of colors, patterns, and textures. This allows for rapid adaptation to changing design trends without the need to invest in new raw material inventories. A single PVC laminating machine can produce a wide variety of products simply by changing the roll of film, making it a versatile and cost-effective tool.

Enhancing Product Durability and Longevity

The primary functional role of a PVC laminating machine is to enhance the durability of a product. The laminated PVC film acts as a protective barrier against a variety of environmental stressors. It provides a high degree of moisture resistance, which is critical for products used in kitchens, bathrooms, or outdoor settings. This barrier prevents the underlying substrate from warping, swelling, or degrading due to water exposure. Furthermore, the laminated surface is highly resistant to scratches, abrasions, and stains, extending the product's lifespan and maintaining its new appearance for years. The film also provides excellent protection against UV radiation, preventing colors from fading and materials from becoming brittle over time. This makes the PVC laminating machine an essential piece of equipment for producing durable and long-lasting goods. The investment in such a machine pays for itself by reducing waste, minimizing product returns due to defects, and enhancing customer satisfaction.

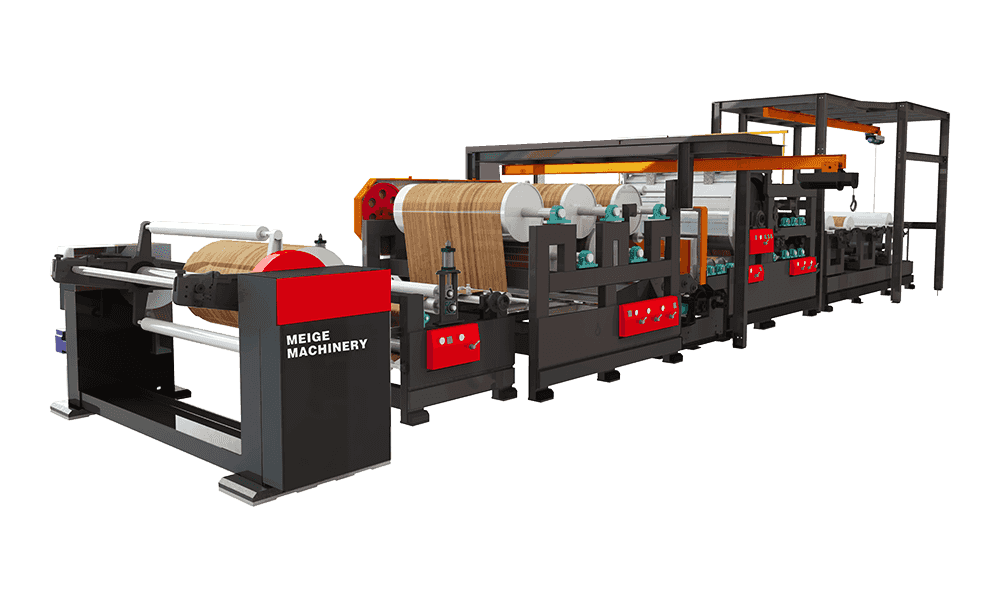

The Role of Technology in Modern Lamination

The evolution of the PVC laminating machine has been driven by technological advancements. Today's machines feature sophisticated control systems that automate the entire process, from feeding and alignment to heating and pressing. These smart systems can be programmed for different materials and films, ensuring consistent results with minimal human intervention. Furthermore, features like automatic film cutting and waste removal systems improve efficiency and reduce material waste. The use of infrared heating elements and advanced pressure systems ensures that heat and pressure are distributed evenly across the entire surface, eliminating common lamination flaws. As materials science continues to advance, new types of films and adhesives are being developed, further expanding the capabilities and applications of the PVC laminating machine. This continuous innovation ensures that this machine will remain a vital tool in manufacturing for years to come.