The rotogravure printing machine is a vital piece of high-speed printing equipment widely used for long-run, high-quality printing applications. Known for its precision and efficiency, this gravure printing machine plays a crucial role in packaging, publication, and decorative printing industries. With its ability to produce fine image details and consistent color density, the rotogravure press stands out as a preferred choice for mass-production printing.

A rotogravure printing machine is a type of intaglio printing press that uses engraved cylinders to transfer ink directly onto the substrate. The printing process involves etching the image onto a rotating metal cylinder, which holds ink in its recessed cells. Excess ink is removed by a doctor blade before the substrate—such as plastic film, paper, or foil—comes into contact with the cylinder, absorbing the ink from the engraved areas.

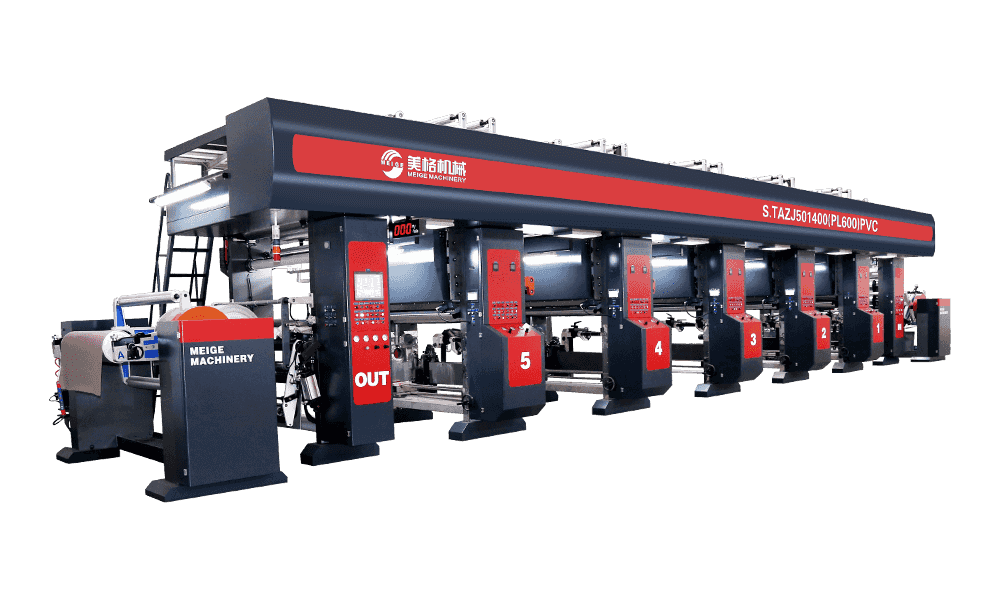

This rotary printing press is engineered for continuous roll-to-roll printing, making it ideal for producing flexible packaging materials, labels, wallpapers, and magazine inserts. Because of its capability to deliver vibrant, high-resolution prints over long runs, the rotogravure printing process is unmatched in industries that demand consistency and durability.

Advantages of Rotogravure Printing Machines

One of the biggest advantages of using a gravure printing machine is its superior print quality. The engraved cells can hold more ink than other printing methods, enabling deeper color saturation and finer image reproduction. This makes it particularly beneficial for photo-rich applications.

Additionally, rotogravure machines are built for speed. Modern systems can operate at impressive speeds—up to 600 meters per minute—without sacrificing image clarity. This makes the high-speed printing equipment highly productive, reducing turnaround times for large-volume orders.

Key benefits include:

Consistent quality over long print runs

High-speed operation for large-scale production

Excellent ink adhesion on a variety of substrates

Durability of engraved cylinders for repeated use

Minimal downtime due to automated systems and precise engineering

Applications of Rotogravure Presses

Rotogravure printing machines are extensively used in the flexible packaging industry. They print on BOPP, PET, PVC, and aluminum foil to produce food packaging, pouches, and laminates. The publication sector also relies on rotogravure presses for printing magazines, catalogs, and brochures with vivid imagery.

Decorative printing is another area where rotary gravure printing machines excel. From wallpaper to gift wrap and decorative films, the ability to maintain consistency in color and texture across wide surfaces makes them indispensable.

Modern Innovations in Rotogravure Technology

In recent years, gravure printing machine manufacturers have focused on improving energy efficiency, reducing waste, and enhancing automation. Features like auto-registration, digital ink viscosity control, and quick-change cylinder systems help optimize production and minimize material loss.

Additionally, eco-friendly rotogravure machines are now available, designed to work with low-VOC inks and equipped with solvent recovery systems to reduce environmental impact.

Choosing the Right Rotogravure Machine

When selecting a rotogravure printing press, consider the following:

Substrate compatibility: Ensure the machine can handle the material you intend to print on.

Printing width and speed: Match the machine's specifications with your production needs.

Cylinder configuration: Choose between single or multiple station setups based on the complexity of your print designs.

Automation features: Advanced control systems can reduce labor costs and improve accuracy.