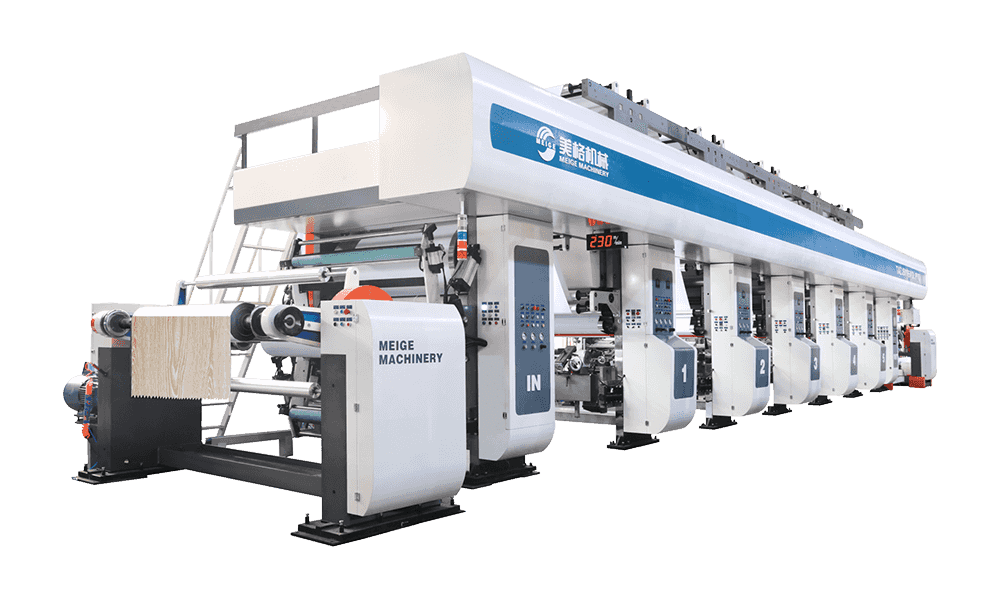

In the packaging and printing industry, the PVC film gravure printing machine has become an essential tool for delivering vibrant, high-resolution prints on flexible substrates. Designed specifically for printing on PVC film, this advanced equipment offers unmatched accuracy, speed, and quality. Whether you refer to it as a gravure press, rotogravure printing machine, or PVC film printing equipment, its role remains central to modern industrial printing processes.

What Is a PVC Film Gravure Printing Machine?

A PVC film gravure printing machine is a type of rotogravure press engineered to print directly onto polyvinyl chloride (PVC) film. This printing technology uses engraved cylinders to transfer ink onto the film surface, resulting in sharp, continuous-tone images. Known for their high-speed capability and durability, gravure presses are widely used in packaging, labels, decorative film, and wallpaper production.

The term gravure printing refers to a process where the image is etched onto a printing cylinder. Ink is applied to the cylinder and then wiped clean, leaving ink only in the recessed cells. As the film rolls over the cylinder, the ink transfers onto the substrate, producing detailed, long-lasting prints.

Key Features of PVC Film Gravure Printing Equipment

Modern PVC film gravure printing machines come with a variety of high-performance features:

Precision Printing: With advanced servo systems and tension control mechanisms, the machine ensures perfect alignment and consistent color registration.

Multi-Color Configuration: These presses are available in 4-color, 6-color, and 8-color formats, allowing for complex and vivid graphic reproduction.

High-Speed Output: Capable of operating at speeds up to 150–300 meters per minute, this printing system increases productivity while maintaining quality.

Drying Systems: Efficient hot-air or infrared drying units reduce ink drying time, enabling faster processing and reduced energy consumption.

Web Inspection: Many machines include automated web guiding and defect detection systems for error-free output.

Applications of PVC Gravure Printing Machines

The PVC gravure printer is ideal for printing on a variety of flexible plastic films, with PVC film being the primary substrate. It is widely used in industries such as:

Packaging Industry: Printing on shrink sleeves, food packaging, and pharmaceutical wrappers.

Decorative Film Printing: Used in the production of wood grain films, marble texture films, and other aesthetic applications.

Label Printing: For self-adhesive labels, product branding, and promotional materials.

These PVC printing machines are also suitable for printing on PE, PET, BOPP, and CPP films, offering versatility for diverse printing needs.

Benefits of Using Gravure Printing Machines for PVC Films

Using a PVC film gravure printer offers several key advantages:

Superior Print Quality: Gravure printing delivers high-resolution and richly colored prints with excellent sharpness and detail.

Long Cylinder Life: Engraved cylinders are durable, making them suitable for long-run jobs without loss of quality.

Consistent Performance: Once set, the machine maintains consistent ink transfer and image reproduction over extended runs.

Cost-Effective for Bulk Printing: Ideal for high-volume production, gravure presses reduce the cost per unit significantly over time.

Choosing the Right PVC Film Printing Machine

When selecting a PVC gravure printing machine, several factors should be considered:

Substrate compatibility: Ensure the machine supports PVC and other films you intend to use.

Production volume: Choose a press with the right speed and color capacity for your expected output.

Automation level: Features like automatic tension control, ink viscosity control, and real-time monitoring can greatly enhance efficiency.

After-sales service: Reliable technical support, spare parts availability, and operator training are crucial for long-term performance.