In the modern packaging and printing industries, maintaining product quality is crucial for competitiveness. One of the essential pieces of equipment used to ensure consistent quality is the rewinding and inspection machine. These machines play a vital role in detecting defects, correcting alignment issues, and preparing materials for the next stage of production. Also referred to as rewinder inspection machines or automatic inspection systems, they streamline the inspection process while minimizing material waste.

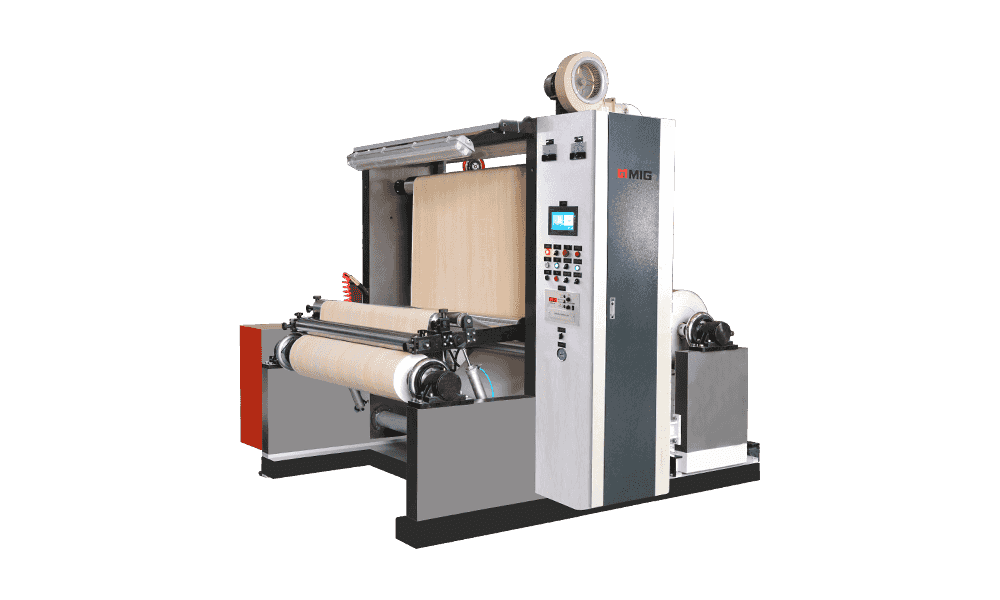

A rewinding and inspection machine is a specialized device used to unwind, inspect, and rewind roll materials such as films, paper, foil, or laminated sheets. This equipment allows operators to detect printing errors, surface defects, and misalignments in the material. The rewinder machine then re-rolls the corrected material in preparation for slitting, lamination, or final packaging.

Modern inspection rewinders are equipped with advanced vision systems, tension controls, and automatic stop functions. These features allow for real-time monitoring of the substrate, increasing production efficiency while ensuring superior quality.

Key Features and Benefits

High Precision Inspection

Rewinding and inspection machines are capable of identifying even the smallest imperfections. Equipped with optical sensors and camera-based systems, they can detect issues like color variation, misprints, scratches, and pinholes.

Efficient Rewinding Process

The rewinding function ensures that rolls are neatly wound with uniform tension. This is crucial for downstream processes such as slitting or die-cutting, where tension irregularities can cause equipment damage or product defects.

Versatile Material Handling

Whether dealing with plastic film, aluminum foil, paper, or laminated substrates, the rewinding inspection equipment is designed to accommodate a wide range of materials. This makes it an ideal choice for packaging converters and printing houses.

Automation and Speed

Many automated rewinder inspection systems feature programmable logic controllers (PLCs) and touchscreen interfaces, enabling operators to set inspection parameters with ease. The machines operate at high speeds, reducing downtime and boosting throughput.

Applications of Rewinder Inspection Machines

These machines are used across various sectors including:

Flexible packaging

Label printing

Pharmaceutical and medical packaging

Food and beverage labeling

Industrial film processing

In all these areas, the rewinding and inspection machine acts as a gatekeeper for quality, ensuring that only defect-free material proceeds to the next stage.

Choosing the Right Rewinding Inspection Machine

When selecting a rewinder with inspection capabilities, several factors should be considered:

Material width and thickness

Type of defects to detect

Required inspection resolution

Speed and tension control mechanisms