Industry knowledge

How does the applied heat affect the sample's physical properties during the pressing process?

When using an electric heating sample press, the application of heat is not just a secondary step—it's a critical component of the compaction process. Heat works hand-in-hand with pressure to fundamentally alter the physical properties of a sample, leading to a higher-quality, more stable pellet for analysis. The key effects are on the sample's malleability, its internal structure, and the activation of any binders.

1. Enhanced Malleability and Flow

Heating the sample lowers its viscosity and increases the plasticity of its particles. Think of it like a cold piece of clay versus a warm one: the warm clay is much easier to mold and shape. This is especially true for materials with polymeric components or for powders with irregular shapes. By making the particles more pliable, heat allows them to deform and flow under pressure, filling in voids and creating a much denser, more uniform compact. This increased density is vital for many analytical techniques, such as X-ray fluorescence (XRF), where a smooth, void-free surface is essential for accurate and consistent results.

2. Binder Activation

In many sample preparation procedures, a binding agent (a fine powder added to the sample) is used to help hold the final pellet together. Heat is the key to activating these binders. It causes them to soften or melt, which allows them to effectively coat and "glue" the individual sample particles together. Without heat, the binder might not fully integrate, leading to a fragile pellet that can crumble during handling or analysis. The resulting heat-activated bond creates a mechanically stable pellet that can withstand the rigors of a laboratory environment.

3. Homogenization and Microstructural Changes

The combination of heat and pressure helps to break up any large particle agglomerates and ensures a more homogeneous distribution of elements within the sample. For multi-component samples, this is crucial for reducing "particle size effects" and ensuring that the analytical instrument "sees" a representative mix of all the components.

Furthermore, for certain materials, heat can induce controlled microstructural changes, such as altering the crystalline structure or phase composition. While this can be a desired effect for some specific analyses, it's also a factor to be mindful of, as it can influence the final mechanical and chemical properties of the pressed sample.

4. Removal of Volatiles and Moisture

Finally, heating the sample before or during pressing helps to drive off any trapped moisture or other volatile compounds. If these are not removed, they can create gas pockets or bubbles during compaction, which compromises the pellet's density and surface quality. The heat ensures a more solid, consistent final product.

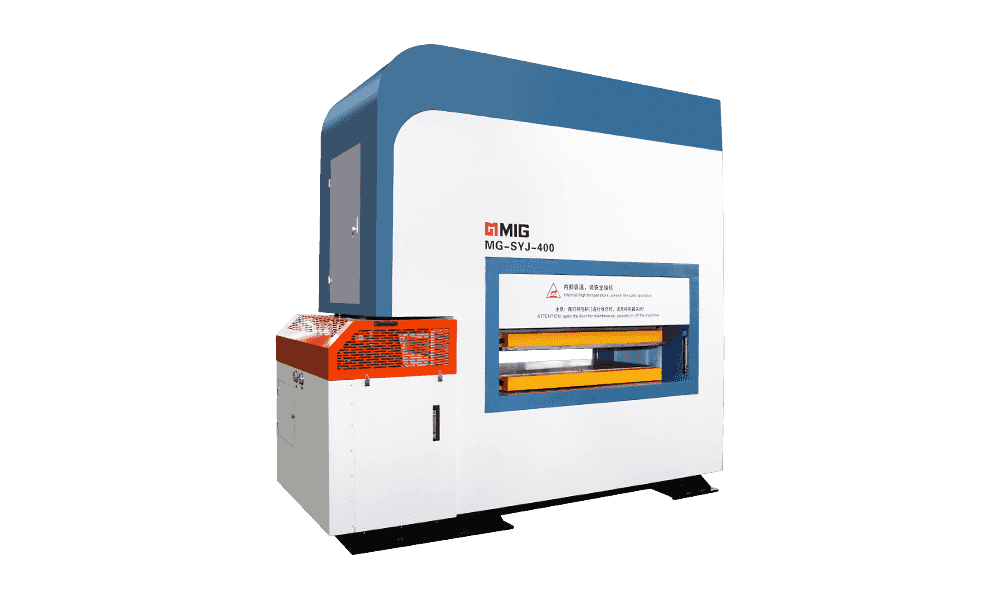

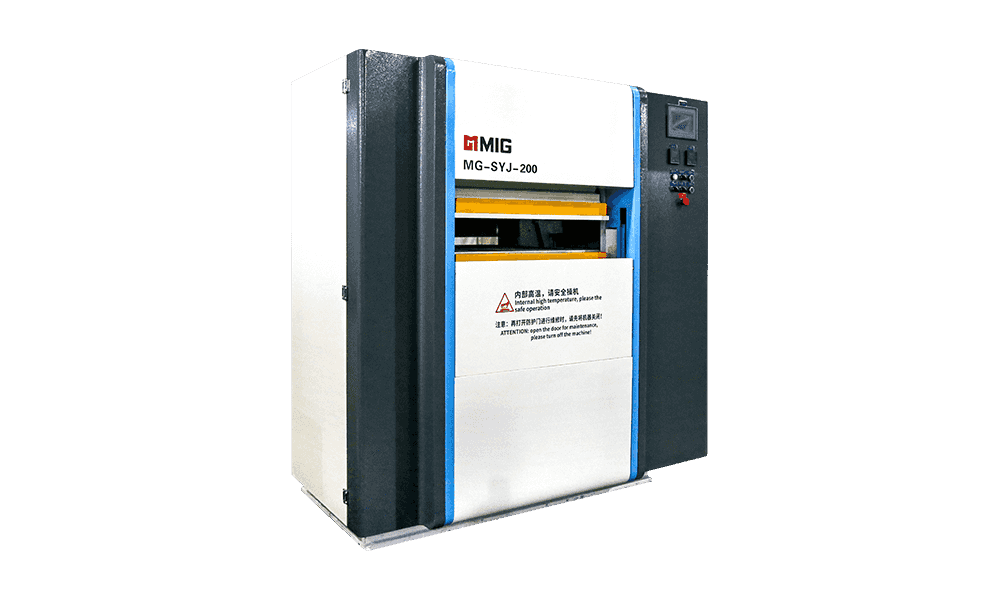

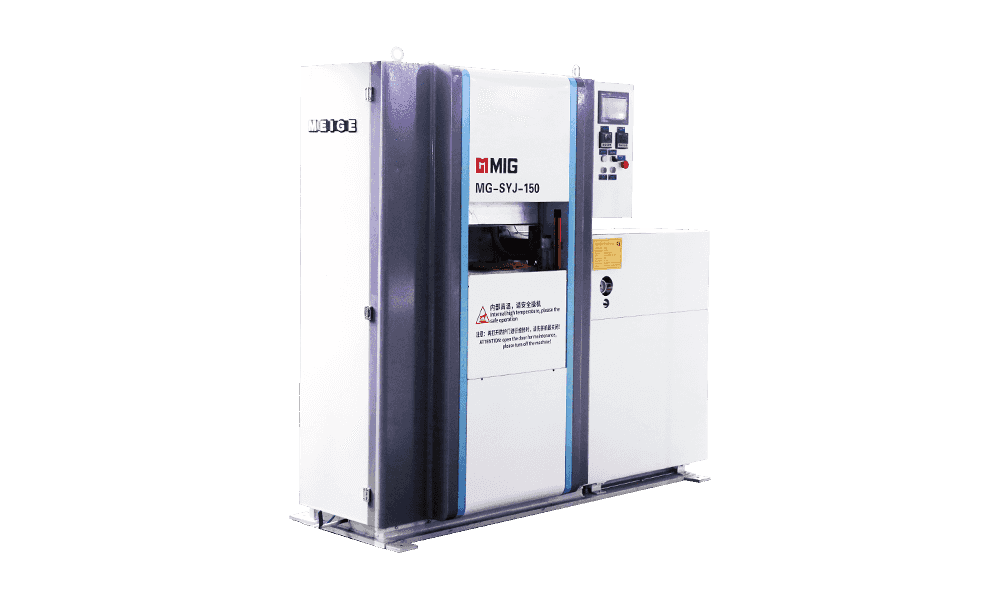

In summary, the Electric heating sample press is a powerful tool that goes beyond simple warming. It actively changes the physical and chemical state of the sample to ensure a dense, homogeneous, and robust pellet, which is a prerequisite for high-quality and reliable analytical data.

English

English 中文简体

中文简体