Industry knowledge

The Stacking Gravure Roller Intelligent Storage System

As a pioneer and innovator in this field, Zhejiang Meige Machinery Co., Ltd. has focused on providing professional, intelligent solutions to the gravure printing industry since its founding in 1999. Located in the Lin’an District of Hangzhou City, this national high-tech enterprise specializes in the research, development, and production of automated and intelligent printing equipment and its supporting systems.

It is a three-dimensional storage solution that integrates automation, information technology, and intelligence. It is not just a simple shelf or warehouse, but a complex network composed of an intelligent control system, stacker cranes, automated shelving, and entry/exit conveying equipment. This system can precisely identify each gravure roller and automatically store or retrieve it according to instructions, achieving efficient, safe, and accurate management of the rollers.

With over 20 years of technology accumulation, Meige Machinery has developed a variety of product series, including gravure printing machines for decorative materials and textiles. The company’s main products, such as the drum decorative paper gravure printing machine series, PVC/PP decorative film gravure printing machine series, and the textile transfer printing paper (film) gravure printing machine series, are all closely related to the management of gravure rollers. It is this deep understanding of the core printing equipment and its supporting needs that has enabled the company to develop an efficient and practical intelligent storage system.

The Pain Points of Traditional Storage Methods

Before the introduction of intelligent storage systems, printing companies typically managed rollers in the following ways:

Manual Handling and Storage: Rollers are heavy (ranging from dozens to hundreds of kilograms), and manual handling is not only inefficient but also highly prone to causing injuries to personnel.

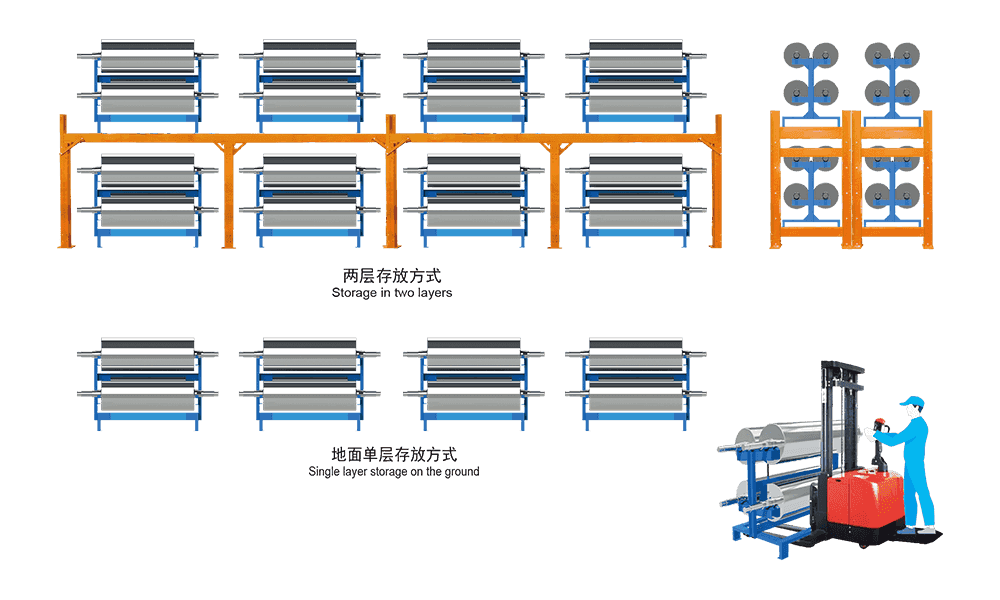

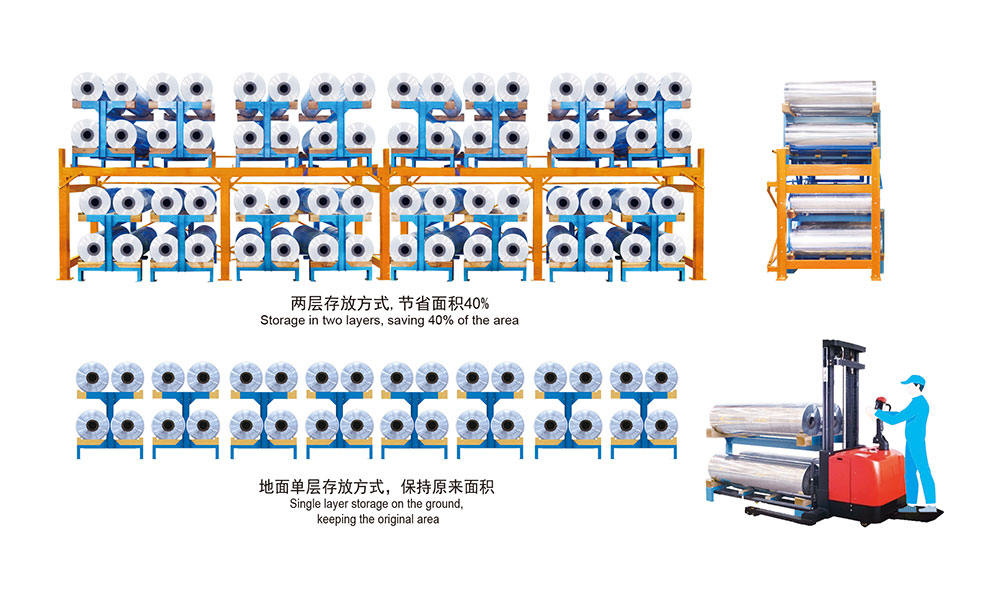

Low Space Utilization: Traditional shelving often has a flat or low design, failing to make full use of the vertical space in the warehouse.

Chaotic Information Management: Roller information (such as number, pattern, usage times, and location) relies on manual records, which are error-prone and difficult to trace.

Safety Risks: Disorganized stacking or improper handling of rollers can lead to scratches or dents on the roller surface, directly affecting print quality and potentially rendering the roller unusable.

Core Technologies and Advantages of the Intelligent Storage System

The emergence of the Stacking Gravure Roller Intelligent Storage is precisely to solve these pain points, relying mainly on the following key technologies:

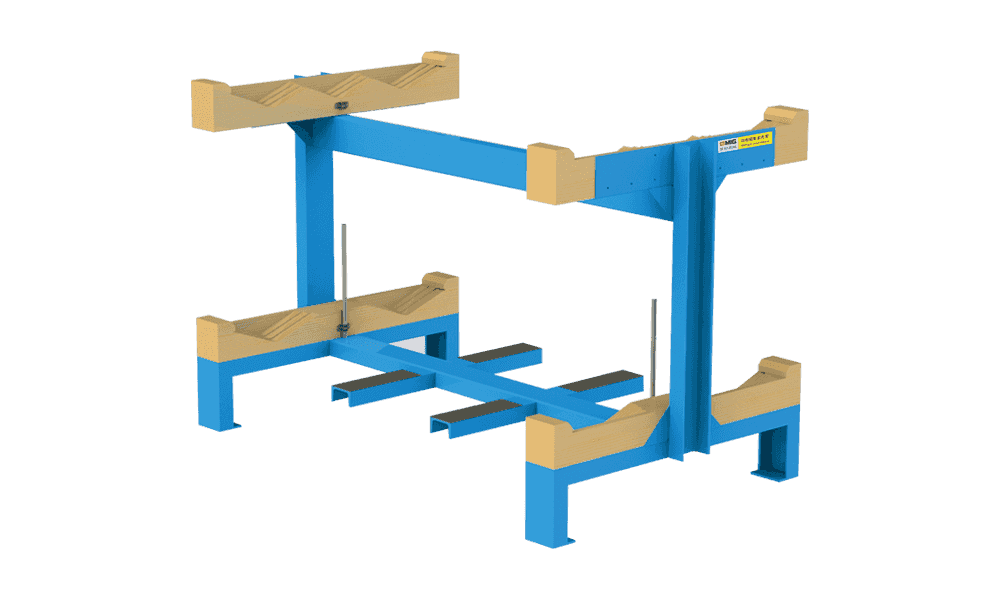

Automated Storage and Retrieval System (AS/RS): This is the physical skeleton of the system. Tall shelves make full use of the vertical space, and stacker cranes shuttle between them to automatically store and retrieve rollers. This significantly improves space utilization and reduces the required footprint.

Intelligent Control and Management System (WMS/WCS): This is the “brain” of the system. It integrates a Warehouse Management System (WMS) and a Warehouse Control System (WCS). The WMS handles business logic such as roller entry, retrieval, and inventory, while the WCS directly controls hardware like stacker cranes and conveyors to execute commands. The entire lifecycle data of all rollers, from production to retirement, is recorded, enabling full traceability.

Identification and Positioning Technology: Each roller is equipped with a unique QR code or RFID tag. When a roller enters the system, the scanning device immediately identifies it and links its information to its storage location. The system can pinpoint the exact coordinates of each storage slot, ensuring the “right roller is taken from and placed in the right location.”

Safety Protection and Human-Machine Collaboration: The system has multiple built-in safety mechanisms, such as anti-collision, anti-tipping, and anti-fall sensors. Safety light curtains are installed at the entry/exit points to prevent personnel from entering dangerous areas during operation. The system also allows for collaboration with manual operation consoles to flexibly meet various productions.

Meige Machinery guides its enterprise development through technological innovation. The company has a professional technical research team, including doctors, experts, professors, and senior engineers, who are dedicated to continuously launching high-performance, high-speed, automated, intelligent, and digitally controlled printing machine products, as well as conducting research on high-quality development projects for traditional industry digitization. The company’s complete product quality system and ERP information network material control management system ensure that every link, from equipment production to after-sales service, is precise and efficient.

The Transformation Brought by the Intelligent Storage System

With the introduction of the gravure roller intelligent storage system, printing companies will experience a significant transformation:

Leap in Production Efficiency: The time to retrieve and change a roller is shortened from minutes to seconds. This greatly reduces changeover time, increases equipment utilization, and boosts overall production output.

Reduced Operating Costs: Automated operations reduce the reliance on manual handling, lowering labor intensity and personnel costs. Simultaneously, the roller damage rate is significantly reduced, cutting down on unnecessary repair and replacement expenses.

Improved Management Level: All data is digitized and visualized. Managers can check inventory levels and roller usage at any time through the system, providing a scientific basis for production scheduling and decision-making.

Ensured Product Quality: The carefully designed storage structure and handling methods maximize protection of the roller surface, preventing printing defects caused by bumps or scratches.

English

English 中文简体

中文简体