Industry knowledge

What types of automation and control systems are typically included in BL, CS, JS, CL, JL, EL Series Decorative Paper Gravure Printer?

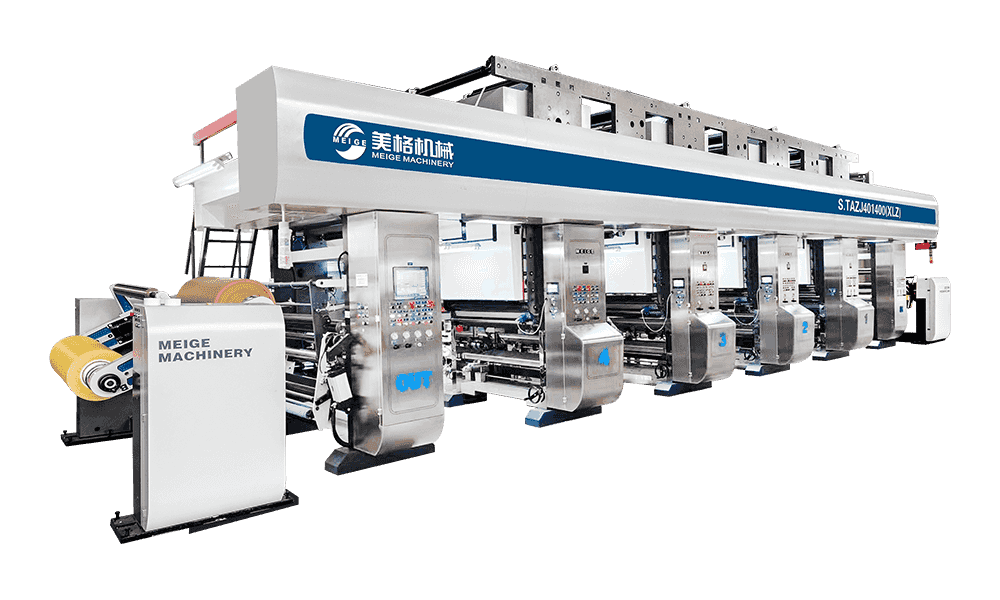

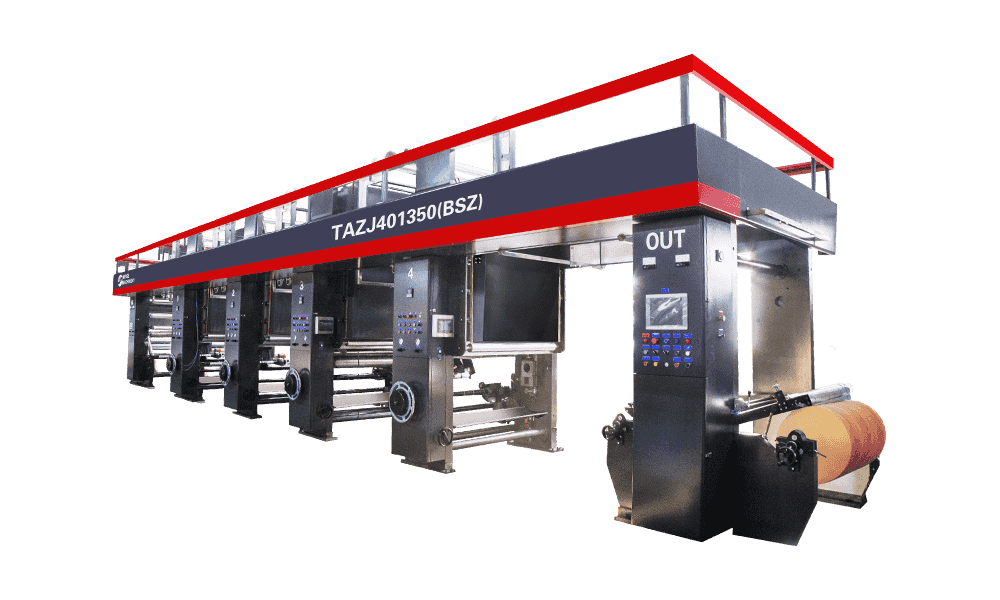

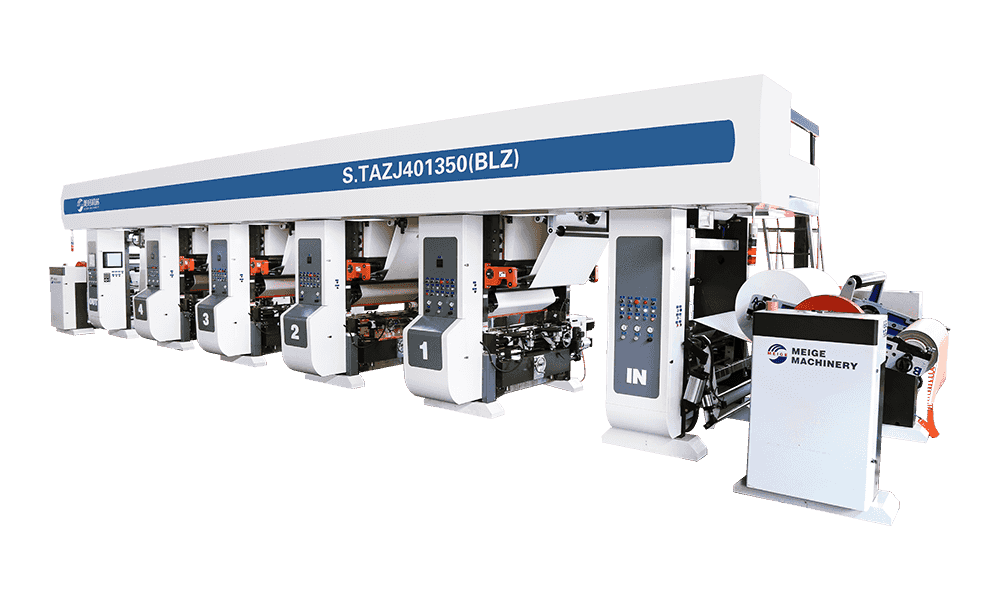

Meige Machinery's BL, CS, JS, CL, JL, EL Series Decorative Paper Gravure Printer integrates state-of-the-art automation and control systems to ensure high quality, efficiency, and consistent output. Here's a breakdown of the typical automation and control systems included in these machines:

1. Web Tension Control Systems

Automatic Unwind and Rewind Tension Control: These systems are crucial for maintaining consistent web tension throughout the printing process, regardless of changes in roll diameter. This is often achieved using AC vector motors and drivers, load cells, and dancer rollers.

Infeed and Outfeed Tension Control: Precise control of tension as the web enters and exits the printing units prevents stretching, wrinkling, or misregistration.

E/P Transducers and Precision Air Regulators: Used for accurate pressure and tension adjustments.

2. Print Register Control Systems (Automatic Register Control)

Longitudinal and Transversal Register Control: These systems utilize sensors (often fiber optics with automatic gain regulation) to detect print marks, ensuring each color is precisely aligned (in register) with the previous one. This is critical for multi-color printing to prevent blurring or misaligned patterns.

Automatic Mark Recognition: The system automatically identifies and tracks registration marks on the moving web.

PID Algorithms: Sophisticated algorithms are employed to immediately correct errors caused by splicing, reel changes, and variations in speed or tension, ensuring high precision.

Touch Screen Interface (HMI - Human Machine Interface): Allows operators to easily monitor, configure, and adjust register settings, often with visual feedback like waveform displays.

Pre-registration Function: Saves time and material by allowing initial plate setting checks after printing only one or two colors.

3. Electronic Line Shaft (ELS) or Shaftless Drive Systems

Servo Motor Technology: ELS systems utilize individual servo motors for each printing unit and other key components (unwind, rewind, infeed, outfeed). This provides highly precise and synchronized control of each section, eliminating mechanical linkages and improving printing accuracy and speed.

Synchronized Control: Ensures all units operate in perfect harmony, which is critical for maintaining print quality at high speeds.

4. Drying Systems Control

Optimized Hot Air Circulation Devices: Automated control of temperature and wind speed within the drying tunnels ensures consistent ink drying and hue, which is particularly important for water-based inks.

Heating Method Options: Control systems for various heating methods, including thermal oil, steam, electricity, and gas.

5. Ink Management Systems

Ink Dipping and Doctor Blade Control: Automated control of the doctor blade's position and pressure ensures even ink scraping and prevents vibration, crucial for consistent ink transfer in gravure printing.

Viscosity and Temperature Control: While not always fully automated, sophisticated machines may include systems to monitor and adjust ink viscosity and temperature for optimal print quality.

6. Automation for Material Handling

Automatic Splicing and Roll Changing: Enables continuous production by automatically splicing new rolls of paper and cutting the web without stopping the machine, significantly reducing waste.

Automatic Loading and Unloading (Air Shafts): Simplifies and speeds up the process of loading and unloading paper rolls.

7. Centralized Control and Monitoring

Programmable Logic Controllers (PLCs): The core of the automation system, managing and coordinating all machine functions based on commands from the HMI and feedback from sensors.

Industrial PC with LCD Touch Screen Monitor: Provides a user-friendly interface for overall machine control, programming, and real-time monitoring of all parameters.

Job Memory: Allows operators to store and recall parameter settings for different jobs, reducing setup time and ensuring consistency for recurring prints.

8. Safety and Protection Measures

Emergency Stop Buttons: Strategically placed for immediate shutdown in case of an emergency.

Protective Devices: Various sensors and interlocks ensure operator safety during operation and maintenance.

These integrated automation and control systems are key to the high performance of Meige Machinery's BL, CS, JS, CL, JL, EL Series Gravure Printing Machine for Engineered Wood Decorative Paper, enabling them to achieve high speeds, exceptional print quality (with high resolution and precise color registration), minimal waste, and efficient production of various decorative paper products.

English

English 中文简体

中文简体