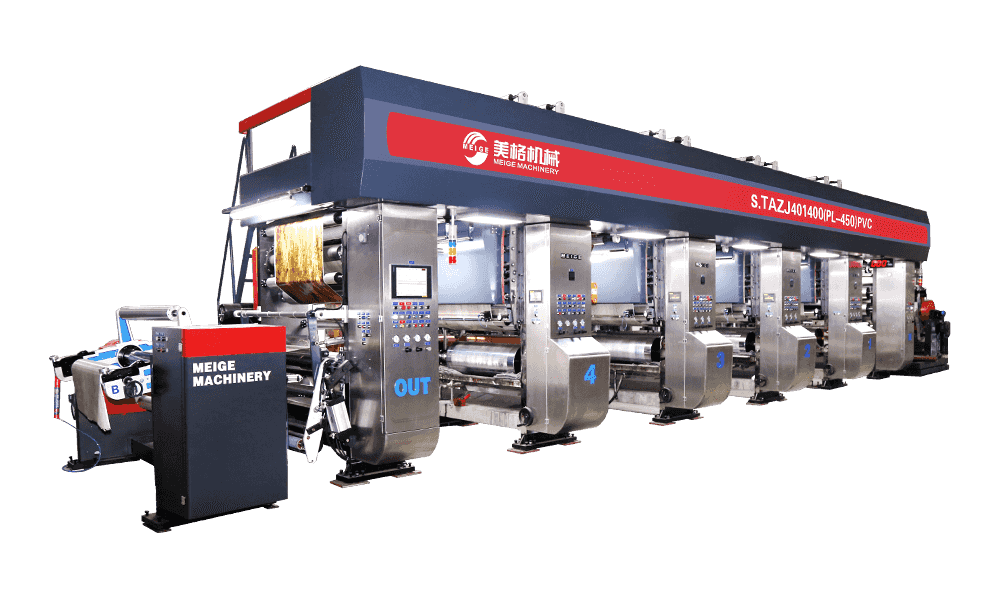

The PVC Film Gravure Printing Machine is a highly specialized piece of industrial equipment central to the production of high-quality decorative and functional surfaces made from polyvinyl chloride (PVC) film. This machine is engineered to meet the stringent demands of industries requiring durable, continuous, and visually complex patterns, such as those used in flooring, furniture laminates, and window films.

Why Gravure for PVC Film?

PVC film is a non-porous and often glossy substrate, making it challenging for standard printing methods. The gravure printing process is ideally suited for this material due to its ability to transfer a consistent and high-density layer of volatile solvent-based ink, which adheres powerfully to the non-absorbent plastic.

The Printing Mechanism

-

Cylinder Etching: The core of the operation lies in the printing cylinder, which has the desired image or pattern meticulously engraved into its surface. These engravings are microscopic cells that hold the ink.

-

Continuous Ink Supply: The cylinder rotates through an ink tray, filling the cells with ink.

-

The Doctor Blade’s Role: A precision-ground doctor blade scrapes away excess ink from the cylinder's non-engraved surface, ensuring that ink remains only in the recessed cells. This guarantees sharp, clean edges and prevents background smudging.

-

High-Pressure Transfer: As the PVC film passes between the inked cylinder and a rubber-coated impression roller, immense pressure is applied. This pressure forces the soft film into the ink cells, resulting in near-total ink transfer and producing an exceptionally crisp and vivid print.

Designing for Industrial Output

A robust PVC Film Gravure Printing Machine is built for high-speed, continuous manufacturing, often handling rolls of PVC film several meters wide. Key operational features include:

1. Multi-Station Capability

Machines are modular, featuring several printing units in sequence . Each unit applies a single color. A typical setup for creating a realistic wood grain or marble effect might use six to ten stations: one for the base color, multiple for detailed grain lines and textures, and sometimes a final station for a clear, protective topcoat or lacquer.

2. High-Speed Drying Systems

Since PVC film is plastic, the printed ink must be dried instantly to prevent smearing before it reaches the next color station. The machine incorporates powerful, energy-efficient drying tunnels—usually forced hot-air convection or infrared systems—located immediately after each printing unit.

3. Precision Registration Control

Achieving perfect overlay (registration) of different colors is crucial for complex patterns. Modern PVC Film Gravure Printing Machines utilize automatic tension and registration control systems. These systems monitor the print alignment in real-time, using sensors to detect registration marks, and automatically adjust the circumferential and lateral position of the cylinders via servo motors, ensuring flawless pattern continuity at speeds up to hundreds of meters per minute.

Versatility in Application

The product’s success is measured by the sheer variety of PVC products it enables. It produces the lifelike textures for Luxury Vinyl Tile (LVT) and Sheet Flooring, the aesthetic finishes for self-adhesive vinyl (SAV), and the durable decorative films for kitchen cabinets and interior wall panels. The machine’s ability to consistently replicate complex textures makes it the foundational technology for mass-produced, high-end decorative PVC films.