The rotogravure machine, often simply called a gravure press, stands as a titan in the world of high-volume, high-quality printing. Its name, a blend of the Italian “rotare” (to rotate) and the German “gravieren” (to engrave), perfectly describes its core function: using a rotating, engraved cylinder to transfer ink onto a substrate.

Unlike other printing methods that use raised or flat surfaces, rotogravure is an intaglio process, meaning the image to be printed is etched or engraved below the surface of the printing cylinder. This unique characteristic is the secret to its success and the reason for its widespread use in specific applications.

The Mechanics of Rotogravure

The process begins with the creation of the gravure cylinder. This solid steel cylinder is coated with copper, and then the image is engraved onto its surface using either a diamond stylus or a laser. The engraving consists of millions of microscopic cells, each varying in depth and size. These cells are what hold the ink, and the variation in cell depth is what allows for the rich, continuous tones that rotogravure is famous for. Deeper cells hold more ink, resulting in darker, more intense colors, while shallower cells create lighter shades. This is a key advantage over other printing methods that rely on halftone dots to create tonal variation.

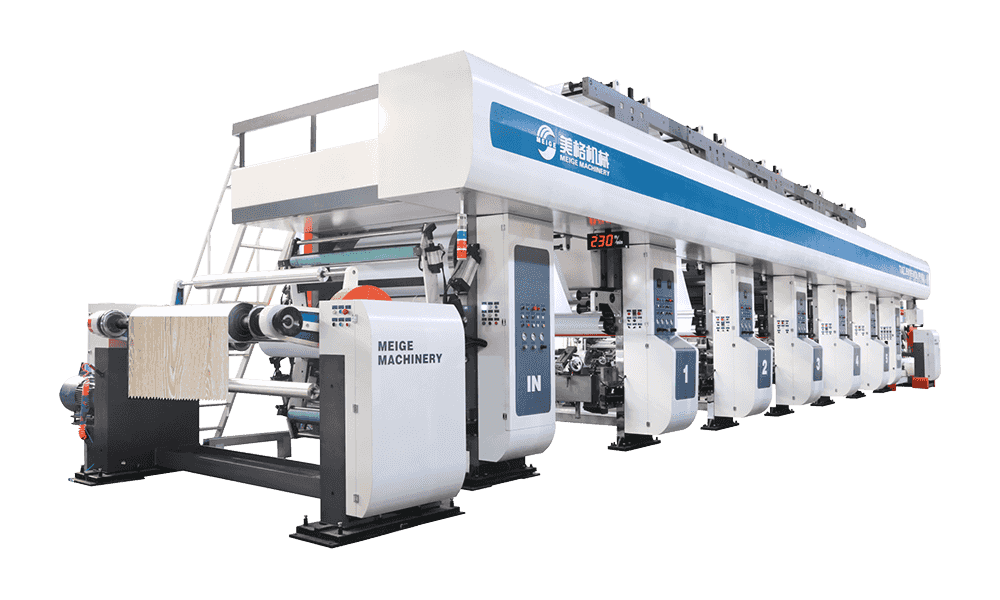

Once the cylinder is prepared, it is mounted onto the rotogravure machine. The process involves several key steps:

- Inking: The entire cylinder is submerged in an ink fountain, filling every engraved cell with a low-viscosity, solvent-based ink.

- Doctor Blade: A crucial component, the doctor blade, is then used to scrape away the excess ink from the non-image areas, leaving ink only in the tiny, recessed cells.

- Impression: The cylinder rotates and makes contact with the substrate (paper, plastic film, foil, etc.), which is pressed against it by a rubber-coated impression roller. This pressure transfers the ink directly from the cells onto the substrate.

- Drying: The substrate then passes through a drying unit, where hot air evaporates the solvent from the ink, leaving a dry, smudge-proof print. This process is repeated for each color, typically Cyan, Magenta, Yellow, and Black (CMYK), with a separate cylinder and inking station for each.

Advantages and Applications

The unique intaglio process of the rotogravure machine gives it several distinct advantages:

- Exceptional Print Quality: It’s unmatched in its ability to produce continuous tones, rich colors, and fine details. This makes it ideal for photographic reproductions and complex designs.

- High-Speed Production: Rotogravure presses can operate at extremely high speeds, making them perfect for long print runs of millions of impressions.

- Durability and Longevity: The gravure cylinders are highly durable and can be reused for years, making the process cost-effective for recurring jobs.

- Versatility: It can print on a wide range of materials, including thin films, foil, cardboard, and other non-absorbent substrates.

Due to these advantages, rotogravure is the preferred method for printing a variety of products, including:

- Flexible Packaging: This is perhaps its most common application, used for food packaging, snack bags, and product wrappers where high-quality graphics are essential for brand appeal.

- Magazines and Catalogs: The process is perfect for glossy magazines and mail-order catalogs that feature high-quality photography.

- Decorative Laminates: It’s used to print wood grain, marble, and other patterns for flooring, furniture, and wall panels.

- Tobacco Packaging and Security Printing: The precise nature of gravure is also used for printing security features on items like stamps and currency.

In summary, the rotogravure machine is more than just a printer; it’s a sophisticated piece of engineering that enables the mass production of high-quality, visually striking printed products. Its ability to combine speed, quality, and versatility solidifies its position as a cornerstone of the modern printing industry.